When it comes to selecting the right Square Tube Machine, the process can feel overwhelming. John Smith, a leading expert in the manufacturing sector, once stated, "Choosing the right equipment can make or break your production line." This is especially true for square tube machines, vital for a variety of industries.

Understanding your specific production needs is crucial. Consider the materials you will work with, the desired output, and the machine's capabilities. High-quality machines offer durability and efficiency. However, not all options provide the best features for your particular tasks. You may find machines that excel in speed but lack precision. This trade-off often leads to dissatisfaction.

Research remains essential in this industry. Read reviews, ask for recommendations, and evaluate your budget. A well-informed choice can improve your operations and reduce waste. In the end, the right Square Tube Machine isn't just about specs; it's about how well it fits your unique demands. Consider your options carefully.

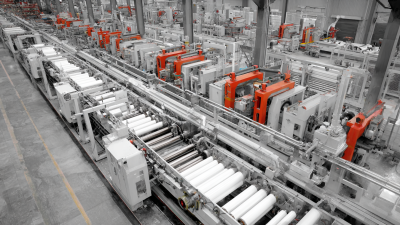

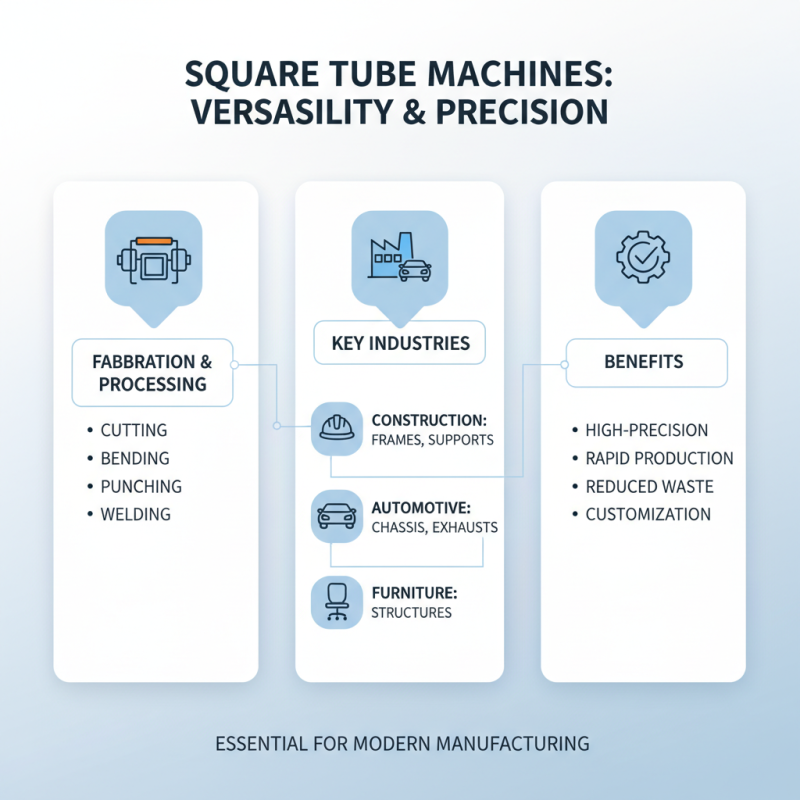

Square tube machines are versatile tools used in various industries. They are essential for fabricating and processing square tubes used in construction, automotive, and furniture manufacturing. These machines can produce high-precision components quickly. Understanding their functions is vital for making the right choice based on your specific needs.

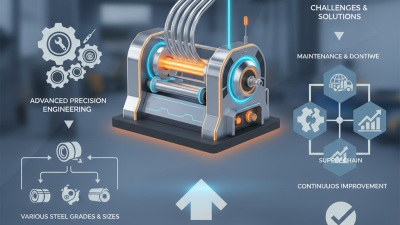

When selecting a square tube machine, consider the materials you will work with. Different machines have varied capabilities regarding metal types and thicknesses. Be aware that not all machines handle the same ranges of dimensions. Some have limitations on size, which can impact your production process. It's crucial to match the machine’s capacity with your project requirements.

Another factor to think about is the machine's ease of use. Some models have complicated controls, which may lead to errors. Operators need training to maximize efficiency. A machine that is difficult to operate can slow down production and create frustration. Reflect on the learning curve involved; it can cost you time and money if operators struggle with the technology.

Choosing the right square tube machine involves several key factors. First, consider the machine's capacity. It should match your production needs. For smaller operations, a lower capacity may suffice. Larger manufacturers might require high-capacity machines. Think about the thickness and dimensions of the tubes you'll be working with. Different machines are better at handling various specifications.

Another important aspect is the machine's ease of use. A user-friendly interface helps operators work efficiently. Complex setups can lead to errors and downtime. Check for features that allow quick adjustments and maintenance. It can save time and reduce frustration. Make sure to research support options as well. When issues arise, having adequate assistance can be crucial.

Don't overlook the cost-effectiveness of the machine. While initial prices can be tempting, think long-term. Will cheaper options lead to more repairs? Investing in a durable machine may reduce future expenses. Reflect on how these factors align with your goals. A thoughtful decision can greatly impact your production process.

When comparing different types of square tube machines, it's essential to look at specific features. Some machines focus on speed while others emphasize precision. A report from the Metal Forming Association revealed that machines with faster cycle times can increase productivity by 25-30%. However, this speed can sometimes compromise accuracy, leading to increased waste.

Another factor to consider is the machine's versatility. Some models can handle various material thicknesses while others are more limited. Research indicates that machines capable of processing a broader range of materials tend to have a higher initial cost. Yet, this can be offset by their ability to adapt to different projects, ultimately enhancing return on investment.

Additionally, user-friendly interfaces are becoming increasingly important. A survey conducted by the Fabricators & Manufacturers Association found that 70% of operators prefer machines that are easy to learn and operate. Machines with complicated controls can lead to inefficiencies and mistakes. For those who do not prioritize training, this can lead to higher operational risks and less productivity. The choice depends on specific project requirements and operator proficiency.

Choosing the right square tube machine involves careful evaluation of specifications. Key factors include production capacity, adaptability, and energy efficiency. According to industry reports, machines with a higher output rate can boost your productivity significantly. For instance, machines producing 20 meters per minute can fulfill large order volumes more swiftly than those at 10 meters per minute.

Customizability is also crucial. Some machines can handle various square tube sizes, which offers greater flexibility. A recent study highlighted that manufacturers often overlook adaptability. This oversight can lead to wasted resources when machines cannot accommodate different specifications. Additionally, energy-efficient models reduce operational costs. The initial investment might seem high, but long-term savings are significant.

Finally, user-friendliness should not be underestimated. Complex machines can have a steep learning curve. A report noted that operators often require extensive training. This can delay production schedules. Evaluating these specifications helps ensure that you make an informed decision tailored to your production needs. It's essential to analyze the trade-offs. An ideal machine should align with your operational goals while being adaptable and cost-effective.

When budgeting for a square tube machine, consider the overall expenses carefully. The initial purchase price is just one aspect. Maintenance costs and spare parts can add up over time. Consider how often the machine will be used. Will it handle light or heavy workloads? This can impact durability and long-term costs.

Evaluate your production needs against the machine's capabilities. Cheaper models might have lower initial costs but could falter under heavy use. Don’t overlook energy efficiency ratings. An energy-efficient machine may save significant operating costs. Analyze your financing options. Sometimes leasing might be more economical than buying outright.

Keep in mind the potential for unexpected expenses. Repairs often arise when least expected. Always have a contingency fund set aside for these situations. Reflect on the total cost of ownership over time. Think about the value the machine brings to your operations. Sometimes, a more expensive option pays off through reliability and performance.