Choosing the right Pipe Welding Machine Tube Mill Production Line can be challenging. The market offers many options. An expert in this field, John Smith, once said, “Selecting the correct machine can significantly impact your production efficiency.” Each machine has unique features to consider.

When assessing these machines, think about your specific production needs. Durability and speed are vital. However, some machines may offer performance but lack reliability. It's essential to strike a balance. Have a clear understanding of your material types as well. Different materials require different welding techniques.

Investing in the wrong Pipe Welding Machine Tube Mill Production Line can lead to increased costs and wasted time. Regular maintenance is also crucial but often overlooked. A well-chosen machine can enhance productivity, yet neglecting machine quality can bring headaches. Consider both present and future production goals.

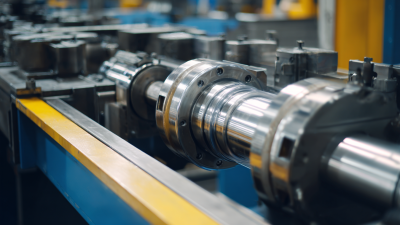

When selecting a pipe welding machine, it’s crucial to understand the different types available. Each type serves unique functions and fits specific applications. Common types include TIG, MIG, and orbital welding machines. TIG machines excel in precision tasks. They work best with thin materials. MIG machines are versatile and faster, suitable for larger production runs. Orbital welders offer automation, ideal for consistent quality in tube mills.

Choosing the right machine involves evaluating your specific needs. Consider the materials to be welded. Some machines perform better on certain metals. Think about the thickness of the pipes. If the material is too thick, TIG might be slow. If it’s too thin, MIG could lead to burn-through. The environment is another factor. If your workshop has dust, it might affect performance.

Reflect on your production goals too. Are you prioritizing speed or quality? Sometimes, the fastest machine might not deliver the best welds. Additionally, training operators on different machines is essential. An inexperienced operator might struggle, regardless of the machine's capabilities. Investing time in understanding machines can ultimately yield better results in the long run.

When selecting a pipe welding machine tube mill production line, specific features play a crucial role. One primary consideration is the machine's welding method. Options include TIG, MIG, or laser welding. Each has its own strengths, impacting speed and material compatibility. The choice can affect production quality and efficiency.

Automation levels are equally important. A fully automated system may boost output but can be costly. Semi-automated machines may require more skilled labor, which could pose risks over time. Balancing automation with your budget is essential.

Tip: Evaluate maintenance requirements. Regular upkeep can prevent unexpected downtime. Check the availability of spare parts. This affects long-term operation and costs.

Another key feature is the flexibility of the production line. Can it accommodate various pipe sizes and materials? Versatility can enhance production capabilities. If the machine can only handle specific formats, you may face constraints.

Tip: Assess the energy consumption of the machine. A more efficient model may save costs in the long run.

Finally, consider the supplier's support and service. Good customer service is important for troubleshooting. Take note of the warranty offered as well. It reflects the manufacturer's confidence in their product.

When selecting a pipe welding machine tube mill production line, it’s vital to assess production capacity and efficiency needs. Research shows that nearly 75% of manufacturers fail to meet their production goals due to inadequate machinery. A machine’s output should match your factory’s demand. If you need to produce over 500 meters of pipes daily, a high-capacity mill is necessary.

Efficiency is also crucial. Studies indicate that an optimized pipe welding line can improve production efficiency by up to 30%. Look for machines that feature automatic adjustments and real-time monitoring systems. These elements can minimize downtime, which is often a silent profit killer. If a machine frequently breaks down or requires manual input, consider it a red flag.

It’s important to think about the materials you plan to work with. Different materials require specific welding techniques. For example, carbon steel might allow for faster welding speeds than stainless steel. This discrepancy can lead to miscalculations. Conducting a thorough assessment of both your material and production volume can help you avoid costly mistakes. Remember, the right choice today can define your productivity tomorrow.

When evaluating costs for pipe welding equipment, it’s essential to assess your budget carefully. The initial investment can be significant. Identifying the specific requirements of your production line is crucial. This includes the types of pipes you will be producing and their respective sizes. Consider the varying capabilities of different machines, as they directly affect price.

More affordable machines might lack certain features. These may result in lower efficiency or higher maintenance costs over time. Therefore, weighing short-term savings against long-term functionality is vital. You may find less expensive options appealing, but quality can impact your overall productivity. Examine technical specifications closely to avoid future disappointments.

Don't forget to factor in operational costs. Training staff on new equipment can incur additional expenses. Also, maintenance costs should not be overlooked. Setting a realistic budget will allow for better financial planning and investment in quality machinery. Keep track of every detail in your budgeting process to avoid surprises later. Revisiting your budget regularly can reveal areas for improvement.

When choosing a pipe welding machine or tube mill production line, manufacturer support plays a crucial role. A reliable manufacturer offers not just a product but also ongoing assistance. In a recent industry report, over 60% of manufacturers noted that strong support improves equipment performance and longevity. Having someone to turn to for issues or maintenance can maximize productivity and minimize downtime.

Warranty options are another vital factor. Warranties provide peace of mind. Approximately 70% of businesses reported that comprehensive warranty coverage was a primary consideration in their purchasing decision. An effective warranty can cover parts and labor, which reduces unexpected costs. However, some manufacturers offer limited coverage, raising concerns.

It's common to overlook the importance of support and warranty. Businesses often focus on the machine's features instead. This can lead to regret later. Relying solely on specifications may not reflect true performance over time. Investing in quality support saves money and stress in the long run. The decision should not be rushed.

| Feature | Importance | Considerations |

|---|---|---|

| Manufacturer Support | Critical for training and troubleshooting | Check for availability of technical support and resources |

| Warranty Options | Protects investment and reduces risk | Look for comprehensive coverage and duration |

| Machine Specifications | Determines suitability for the intended use | Evaluate power, speed, and build quality |

| After-Sales Service | Ensures long-term operational efficiency | Assess response time and service options |

| User Reviews | Provides insights into real-world performance | Research feedback from multiple sources |