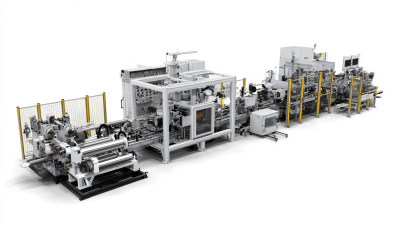

When it comes to the production of high-quality MS pipes, selecting the right manufacturers for MS Pipe Making Machines is critical for your operation's success. With an abundance of options available, understanding the key factors that contribute to the reliability and efficiency of these manufacturers can significantly impact your production quality and operational efficiency. The choice of the right MS Pipe Making Machine Manufacturers not only affects the initial investment but also influences long-term maintenance costs and productivity.

In this guide, we will explore the essential criteria to consider when evaluating potential MS Pipe Making Machine Manufacturers. Factors such as technological advancements, customer service, and the manufacturers' track record in the industry will be discussed to help you make an informed decision. By prioritizing these elements and understanding your specific production needs, you will be better equipped to select a manufacturing partner that aligns with your business goals and ensures the longevity of your production line.

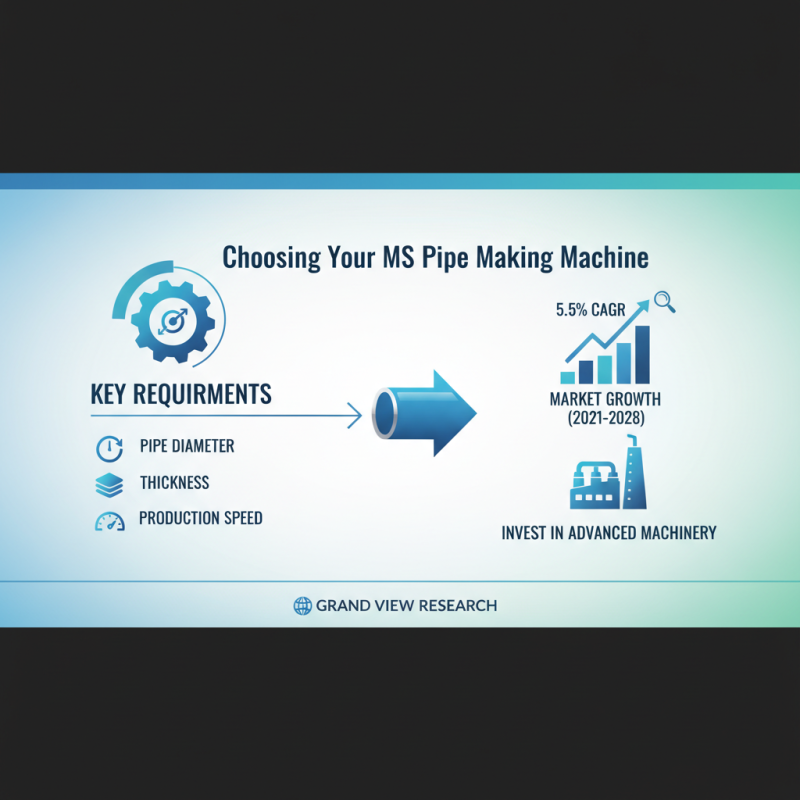

When choosing the right MS pipe making machine, it is crucial to first understand your specific requirements. Factors such as the desired pipe diameter, thickness, and production speed will heavily influence your selection process. According to a recent industry report by Grand View Research, the global demand for steel pipes is projected to grow at a compound annual growth rate (CAGR) of 5.5% from 2021 to 2028, indicating a robust market for pipe making machinery. This growth underscores the need for manufacturers to invest in advanced MS pipe making machines that not only meet current standards but also anticipate future demands.

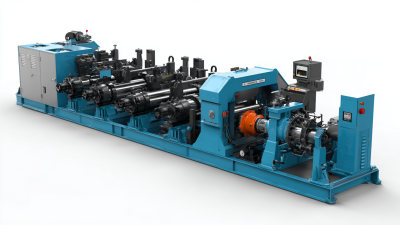

One important consideration is the production capacity of the machine. If your needs are significant, opt for machines with higher output rates and automation features. Additionally, evaluate the machine's energy consumption, as operational costs can add up quickly. The same industry report reveals that energy-efficient machinery can reduce operational costs by up to 30%, making it a wise investment for manufacturers looking to maximize their profitability.

**Tips:** Always request a demo from potential manufacturers to assess the performance and reliability of their machines. It’s also beneficial to gather feedback from other users in your industry to make an informed decision. Investing time in understanding your needs can lead to better quality production and long-term savings.

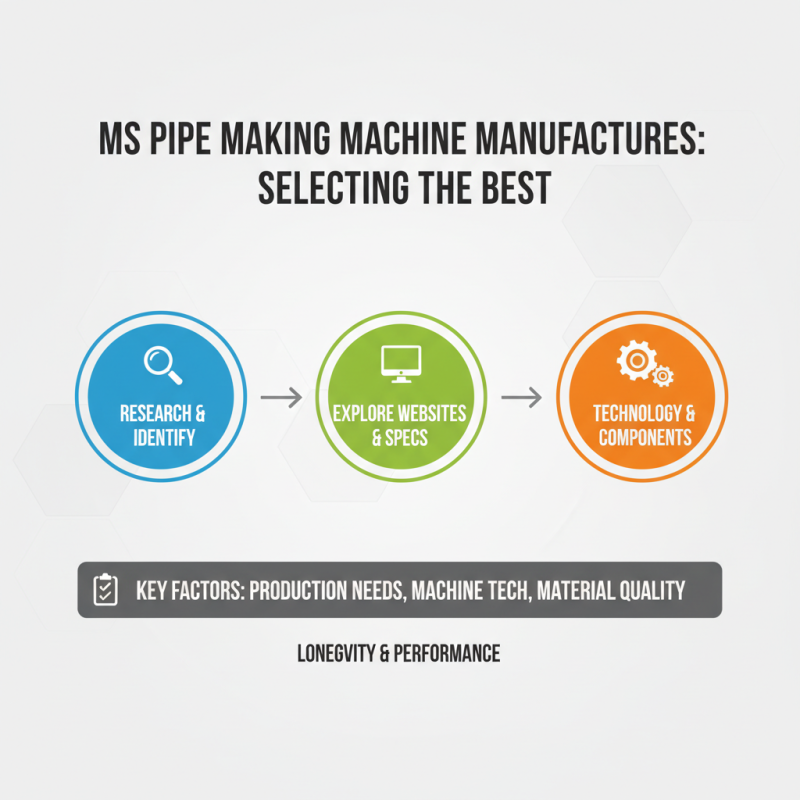

When it comes to selecting the best MS pipe making machine manufacturers, thorough research is essential. Start by identifying potential manufacturers that specialize in the production of MS pipe machines. Explore their websites to gather information about the machinery they offer, focusing on specifications that align with your production requirements. Pay attention to the technology used in their machines, as well as the materials and components they utilize, which can greatly influence longevity and performance.

Additionally, consider the manufacturer’s reputation in the market. Look for customer reviews and case studies that highlight their experiences with the machinery and support services. Engaging in discussions with current users can provide valuable insights into the reliability and efficiency of the machines. It is also advisable to assess the level of after-sales support and maintenance services offered by the manufacturer, ensuring you will have assistance when needed. This comprehensive research will support you in making an informed decision for your specific manufacturing needs.

When selecting the best MS pipe making machine manufacturers, evaluating quality standards and certifications is critical. The International Organization for Standardization (ISO) provides several standards relevant to manufacturing processes, such as ISO 9001 for quality management systems. Manufacturers that adhere to these standards demonstrate a commitment to consistent quality and continuous improvement in their production processes. According to a recent market report, companies that implement ISO standards see a 20% increase in efficiency and product reliability compared to those that do not.

Additionally, certifications such as CE marking for compliance with European health and safety standards can significantly influence the decision-making process. A study by the Global Industry Analysts revealed that equipment from certified manufacturers experiences fewer failures and safety incidents, reinforcing the importance of choosing a compliant supplier. Moreover, engaging with manufacturers that hold industry-specific certifications can provide assurance regarding their technological capabilities and adherence to performance benchmarks. By focusing on quality standards and certifications, businesses can mitigate risks and ensure they invest in machines that meet their operational needs and regulatory requirements.

When selecting an MS pipe making machine, it’s crucial to compare costs and value for money effectively. The initial acquisition cost of the machine is an obvious consideration, but it’s equally important to evaluate the long-term financial implications. This includes operational costs such as energy consumption, maintenance, and spare parts availability. A machine that appears cheaper upfront might incur significantly higher expenses over its lifespan if it requires frequent repairs or if it consumes more energy than average. Thus, conducting a thorough analysis of both short-term and long-term costs will help ensure a prudent investment.

Moreover, the value for money extends beyond mere numerical costs. Factors such as machine productivity, durability, and the quality of finished products also play a crucial role. A more expensive machine with better specifications might deliver faster production rates and superior quality, leading to increased profitability over time. Evaluating aspects like warranty support, after-sales service, and the availability of technical assistance is also essential. These elements contribute to the overall value of the machine and can significantly impact operations. In the competitive landscape of MS pipe production, carefully weighing cost against these qualitative factors will lead to a well-rounded decision that meets both immediate needs and long-term business objectives.

When selecting a manufacturer for MS pipe making machines, customer support and after-sales services play a crucial role in ensuring a satisfactory investment. A reliable supplier should not only provide a high-quality machine but also demonstrate a commitment to customer satisfaction through their support services. Potential customers should evaluate the availability of technical support, responsiveness to inquiries, and comprehensiveness of training programs related to the machine operation and maintenance.

Tips: Look for manufacturers that offer 24/7 customer support to quickly address any operational issues. Additionally, inquire about the availability of online resources, such as FAQ sections or video tutorials, which can enhance your understanding of the machine.

After-sales service is another critical aspect to consider. A reputable manufacturer should offer warranties and a clear return policy, as these are indicative of their confidence in the product. Furthermore, assess the parts and repair services they provide. A good supplier will have a straightforward process for obtaining spare parts within a reasonable timeframe, minimizing downtime for your production line.

Tips: Request testimonials from other clients regarding their after-sales experiences to gauge the reliability of the manufacturer’s service. Also, consider the long-term implications of their support structure, ensuring that they are prepared to assist as your needs evolve.

| Manufacturer | Customer Support Ratings | After-Sales Service Quality | Response Time (Hours) | Warranty Period (Years) | Additional Services |

|---|---|---|---|---|---|

| Manufacturer A | 4.5/5 | Excellent | 2 | 2 | Training & Installation |

| Manufacturer B | 4.2/5 | Good | 3 | 3 | Spare Parts Availability |

| Manufacturer C | 4.0/5 | Satisfactory | 4 | 1 | 24/7 Support |

| Manufacturer D | 4.8/5 | Outstanding | 1 | 5 | Custom Solutions |

| Manufacturer E | 3.8/5 | Average | 5 | 2 | Basic Training |