In the ever-evolving landscape of industrial manufacturing, the selection of the right High Frequency Pipe Welding Machine is critical for optimizing welding processes and enhancing productivity. According to a recent industry report by Research and Markets, the global market for pipe welding equipment is projected to grow significantly, driven by advancements in technology and increasing demand for high-quality welds across various sectors. High-frequency welding technology, known for its precision and speed, is becoming increasingly sought after, with 60% of manufacturers indicating that enhanced weld quality is their top priority.

When choosing a High Frequency Pipe Welding Machine, several factors should be considered, including power requirements, machine capabilities, and the specific materials being welded. The Welding Industry Research Institute has highlighted that improper machine selection can lead to a decrease in operational efficiency and increased costs. By evaluating various features such as frequency range, ease of use, and durability, manufacturers can make informed decisions that align with their operational needs and budgets. As the welding industry continues to innovate, the right machine can ensure not only compliance with industry standards but also a competitive edge in the marketplace.

High frequency pipe welding machines are essential tools in industries requiring high-quality joins in various pipes, especially in sectors such as oil and gas, chemical processing, and construction. These machines use high-frequency currents to induce heat rapidly and efficiently, allowing for precise welding without significant heat distortion. Understanding the components and mechanisms of high frequency welding can greatly influence your choice in selecting a suitable machine.

When choosing a high frequency pipe welding machine, it's crucial to consider factors such as power output, frequency range, and material compatibility. Assessing the specific requirements of your projects will help identify the machine that best meets your needs. For example, higher power output may be necessary for thicker pipes, while a broader frequency range offers versatility across different materials.

Tips: Always check for user reviews and industry feedback on the machines you're considering. This can provide insight into the machine's reliability and performance. Additionally, consult with experts or machinery specialists to better understand the technical specifications and recommendations tailored to your specific welding tasks. Understanding these aspects will ensure you make an informed decision that enhances your welding efficiency and quality.

When selecting a high frequency pipe welding machine, several key factors warrant careful consideration to ensure that the equipment meets your specific needs. First, the power output is critical; it determines the thickness of the pipes you can work with and influences the welding speed. Machines available in different wattages allow for flexibility depending on the materials and their dimensions. Hence, assessing your typical project requirements will guide you toward the appropriate power level.

Another vital aspect is the machine's duty cycle. This specification indicates how long the machine can operate before it requires a cooldown period. For high-volume projects, a machine with a higher duty cycle is preferable, while occasional use may not necessitate this feature. Additionally, consider the machine's portability and ease of setup. If your projects are location-based, a lightweight and compact design will save time and effort. Finally, don't overlook the availability of after-sales support and spare parts, as these factors significantly affect the long-term usability and maintenance of the equipment.

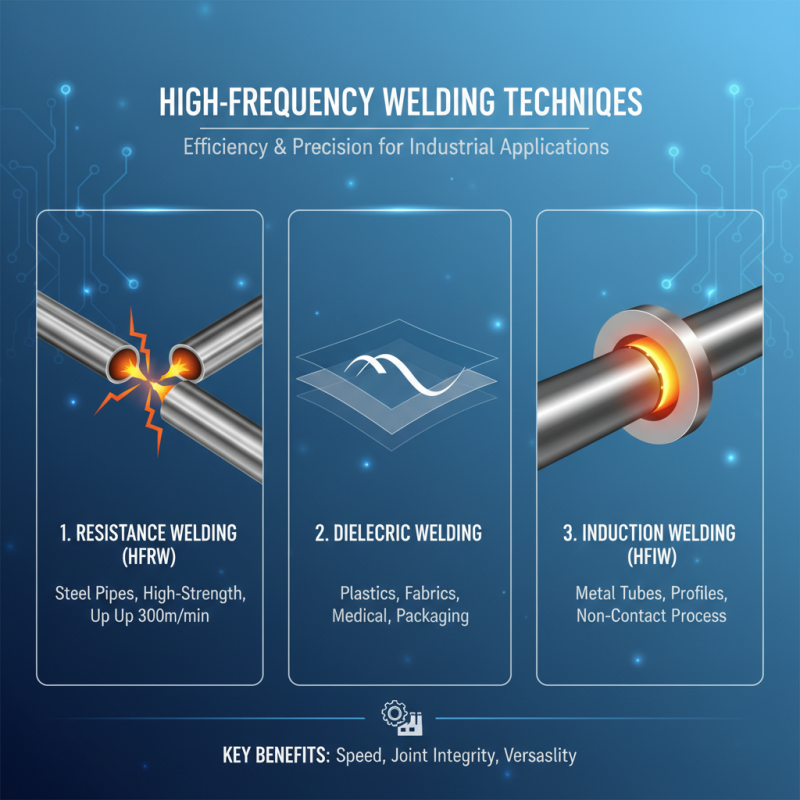

High frequency welding techniques are a cornerstone in various industrial applications, particularly for pipe welding, due to their efficiency and precision. There are primarily three types of high frequency welding techniques: high frequency resistance welding (HFRW), dielectric welding, and high frequency induction welding (HFIW). Each method has unique characteristics tailored to specific operational needs. For instance, HFRW is often preferred in the manufacture of steel pipes, as it provides tight control over joint integrity, making it ideal for high-strength applications. Reports indicate that HFRW is capable of producing welding speeds of up to 300 meters per minute, significantly increasing productivity compared to conventional methods.

Dielectric welding, on the other hand, utilizes the dielectric properties of materials to generate heat. This technique is prevalent in fabricating plastic pipes where the material’s melting point is critical. It is known for its energy efficiency, reducing consumption by up to 30% compared to traditional heating techniques, thus representing a sustainable option for manufacturers. Lastly, HFIW is recognized for its ability to weld thicker materials and larger diameter pipes, allowing for versatile application in sectors such as oil and gas. According to industry analysis, the market for high frequency induction welding is projected to grow at a CAGR of over 5% in the coming years, driven by increasing demand for lightweight and durable pipe structures. Each technique plays a pivotal role in optimizing production processes and ensuring high-quality outputs tailored to industry standards.

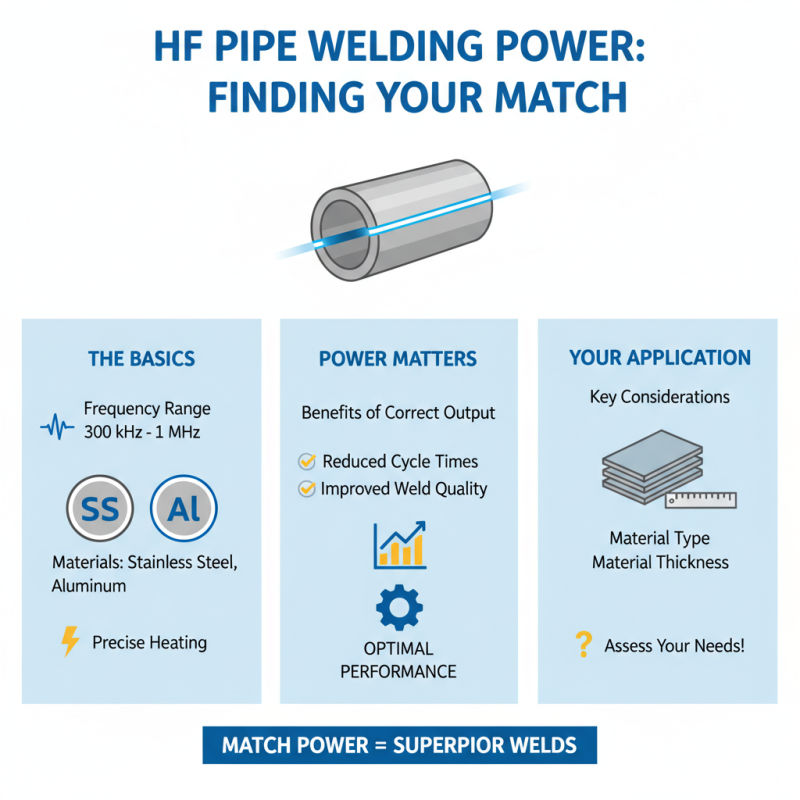

When selecting a high-frequency pipe welding machine, understanding the power requirements specific to your application is crucial. Different types of welding processes demand varying power levels. For instance, high-frequency (HF) welding typically operates within a frequency range of 300 kHz to 3 MHz, allowing for precise control and effective heating of metals such as stainless steel and aluminum. According to industry reports, utilizing the correct power output can significantly reduce cycle times and improve weld quality, making it essential to assess the material types and thicknesses you'll be working with.

For applications involving thin-walled pipes, machines requiring around 5 to 15 kW may suffice, efficiently providing the necessary energy to achieve good penetration without overheating the material. Conversely, heavier industrial applications may necessitate machines with power ratings exceeding 30 kW to ensure proper melting and bonding, especially when dealing with thicker pipes. It's important to match the power output not only to the specifications of the pipe material but also to the production rate needed; a recent survey indicated that operational efficiency can be optimized by as much as 25% when the power settings are aligned precisely with the job specifications. Thus, accurately assessing power requirements is fundamental to achieving consistent results in high-frequency pipe welding operations.

When selecting a high frequency pipe welding machine, budget considerations play a pivotal role in ensuring that you achieve cost-effectiveness without compromising on quality. It's essential to start by determining the maximum amount you are willing to invest. This will help narrow down your options and focus on machines that deliver the best value within your financial constraints. Evaluate not only the initial purchase price but also the long-term operational costs, including maintenance and energy consumption. A machine that appears cheaper upfront may incur higher costs over time if it requires frequent repairs or is less energy-efficient.

In addition to the upfront and operational costs, consider the functionality and features of the machine in relation to your specific welding needs. Investing in a machine with appropriate capabilities for your projects can save money in the long run, as it can reduce material waste and improve welding efficiency. Furthermore, look for machines that offer scalability; those that can adapt to future project demands without necessitating a complete replacement can provide significant savings. Balancing your immediate financial limitations with the potential for long-term cost-saving features will ensure you make a wise investment in a high frequency pipe welding machine that meets both your current and future needs.

| Model | Power (kW) | Frequency (kHz) | Price (USD) | Efficiency (%) | Warranty (Years) |

|---|---|---|---|---|---|

| HF-100A | 10 | 27.12 | 5000 | 85 | 2 |

| HF-150B | 15 | 30.00 | 7200 | 88 | 3 |

| HF-200C | 20 | 32.77 | 9000 | 90 | 3 |

| HF-250D | 25 | 35.00 | 10500 | 92 | 4 |

| HF-300E | 30 | 40.00 | 12000 | 94 | 5 |