Selecting the right High Frequency Pipe Welding Machine is crucial for achieving quality in welding projects. Experts in the industry emphasize the importance of matching machine specifications to project requirements. John Smith, a renowned welding engineer, once said, "The right machine transforms welding from a task into an art." His words resonate deeply in the context of high frequency welding.

When considering your options, evaluate the machine's power output and frequency range. These features significantly impact weld quality and efficiency. A machine that is too weak may lead to weak welds. Additionally, a powerful machine can be overkill for smaller projects.

It's also essential to consider the machine's capability for various pipe sizes and materials. Some models excel in steel, while others may perform poorly with other materials. Understanding your specific needs can help prevent costly mistakes. Choosing a High Frequency Pipe Welding Machine is not just about specifications. It's also about finding a balance that fits your welding goals and practical constraints.

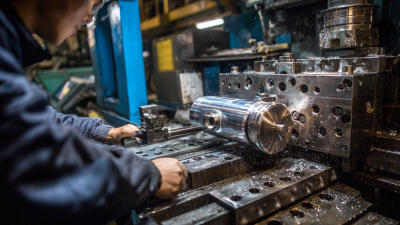

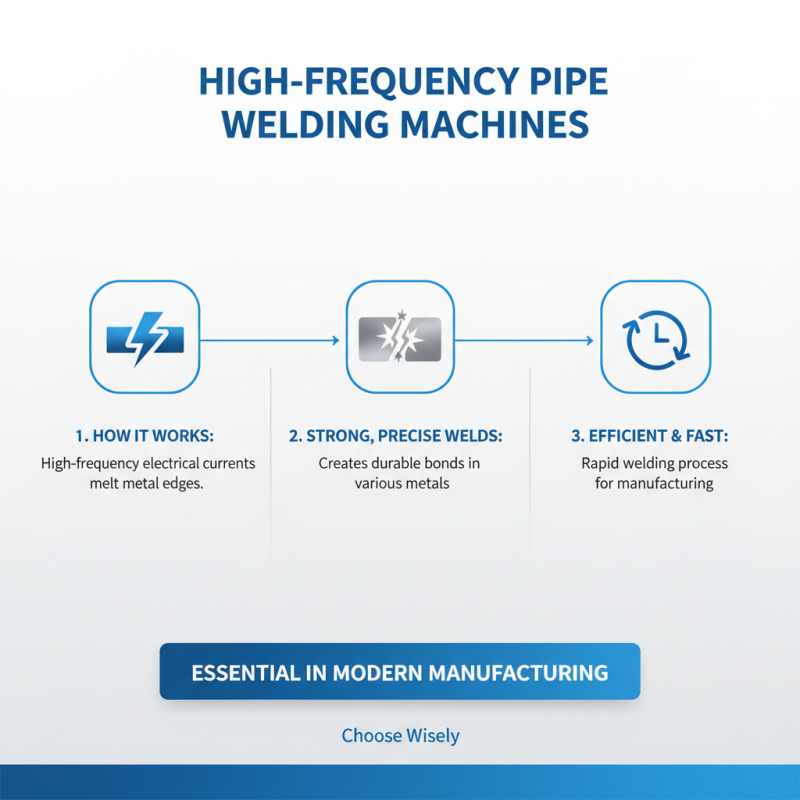

High frequency pipe welding machines are essential in modern manufacturing. These machines utilize high frequency currents to melt metal, creating strong welds in various materials. They are efficient and precise. Understanding their basics can help you choose the right machine.

When selecting a welding machine, consider power output and frequency range. A machine with adjustable settings offers flexibility for different projects. The size and weight matter too. A portable machine is crucial if you work in varied locations. Look for user-friendly controls. Complicated interfaces can slow you down.

Reflect on your specific needs. What types of pipes will you typically weld? Consider the thickness and material. Some machines excel in thin materials, while others are better for heavy-duty jobs. Researching these details will save you time and frustration later.

When choosing a high-frequency pipe welding machine, there are several key factors to consider. The welding thickness is crucial. Machines are rated for specific thickness ranges. For example, a unit suited for thin pipes may struggle with thicker materials. Consider the intended application. According to industry reports, different sectors require different welding specifications.

Another important aspect is the type of welding process. High-frequency welding machines use various methods, such as TIG or MIG. Each has unique advantages and limitations. Misunderstanding these can lead to suboptimal results. Choose a machine that aligns with your specific needs.

**Tips:** Always check the machine’s duty cycle. A higher duty cycle means it can operate longer without overheating. Be cautious with budget constraints. Sometimes cheaper machines sacrifice quality and performance. Look for reviews from professionals who have used the machines.

One must also think about ease of use. An intricate setup can waste time and resources. Complexity may lead to errors during operation. Research ergonomics, too; comfortable equipment reduces user fatigue. Don’t overlook maintenance requirements. Some machines demand frequent servicing, which can be a drawback.

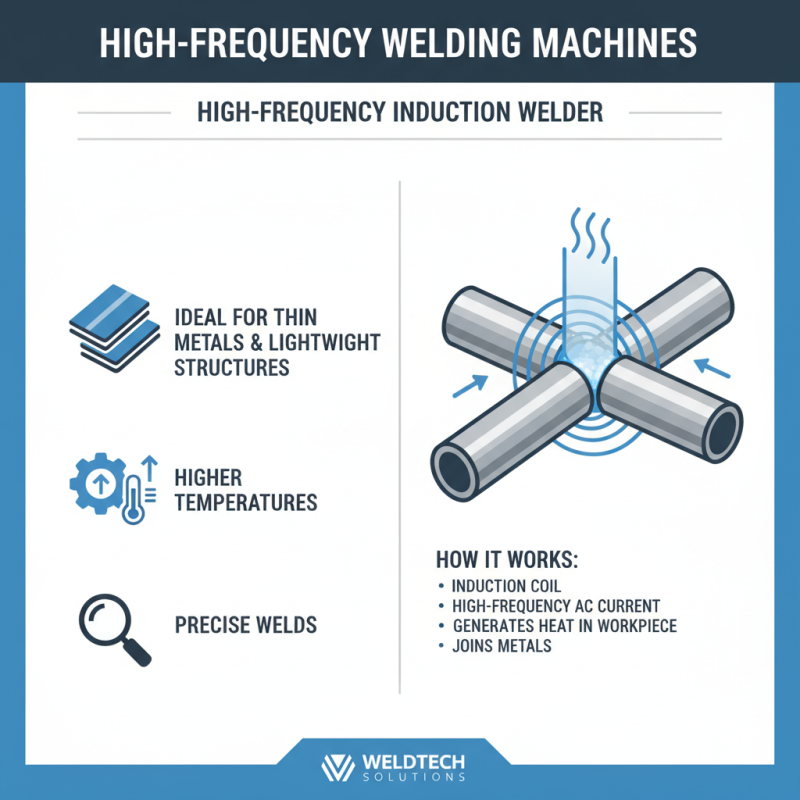

High frequency welding machines come in various types, each suited for different applications. A commonly used type is the high frequency induction welder. It excels in joining thin metals, making it ideal for lightweight structures. This machine operates at higher temperatures and ensures precise welds.

Another type is the contact welding machine. It is more versatile and can handle a range of materials. While it’s effective, it may struggle with thicker materials. User experience varies with this option. Operators need to fine-tune settings for best results.

Consider your specific needs before making a decision. Each machine has its advantages and limitations. Understand the nature of the materials to be welded. Test different machines if possible. Remember, the right equipment improves efficiency, but user skill also plays a crucial role.

When selecting a high-frequency pipe welding machine, understanding specifications is vital. Look closely at the power output. Machines typically range from 5 kW to 200 kW. Higher wattage can reduce welding time but may come with additional costs. Assess your project needs; a smaller operation might not need such power.

Performance ratings also matter, particularly duty cycle and efficiency. A machine with a 60% duty cycle may not handle continuous work well. Similarly, efficiency ratings can indicate energy consumption. Reports suggest that machines with efficiencies above 80% save significant costs in the long run. Yet, it’s crucial to ensure that high efficiency doesn't compromise weld quality.

Don't overlook the technology used in the machine. Some models may rely on outdated tech, affecting performance over time. User reviews highlight that some welders encounter issues with consistent output. So, it's wise to gather insights from industry reports and user experiences before making a final decision. This process helps in making a well-informed choice based on your specific requirements.

When choosing a high frequency pipe welding machine, cost and quality are crucial factors. It's easy to get lured by low prices. However, such machines may lack durability and efficiency. For example, a cheaper model might use lower-grade materials, leading to frequent repairs. This can increase overall expenses over time, negating initial savings.

Quality machines often come with a higher price tag. They typically offer better performance and longer lifespan. Consider factors like precision and speed. A well-built machine can save you time and effort on each project. However, it’s essential to evaluate your specific needs. Are you working on small projects or large-scale jobs? This distinction can impact your decision significantly.

Finding that perfect balance between cost and quality requires reflection. Sometimes, the most expensive option isn’t the best fit for your specific tasks. Evaluate warranties and customer support as well. A strong warranty can be a sign of trust in product quality. Researching user reviews can also provide insights into real-world performance. Ask yourself: what value does quality bring to my projects?