The selection of the best MS pipe making machine manufacturers is crucial for businesses aiming to enhance their production efficiency and product quality. According to a recent report by the International Machine Tool Industry Association, the demand for steel pipes, particularly MS pipes, is projected to grow by 5.4% annually through 2025. This rise underscores the importance of investing in advanced machinery that not only meets production goals but also adheres to industry standards.

Expert insight is invaluable when navigating this choice. Dr. Mark Thompson, a renowned industry analyst and consultant, states, "Choosing the right MS pipe making machine manufacturer can significantly influence the operational productivity and economic viability of your manufacturing process." This sentiment highlights the need for manufacturers to carefully evaluate potential partners based on their technological capabilities, reliability, and after-sales support.

In a competitive market, understanding the nuances of what differentiates MS pipe making machine manufacturers can lead to informed decision-making. Key factors such as production capacity, technological innovation, and customer service should weigh heavily in these evaluations, guiding businesses to select manufacturers that will propel them toward sustainable growth and success in the industry.

When selecting MS pipe making machine manufacturers, several critical factors should be considered to ensure that you choose the best supplier for your needs. First and foremost, evaluate the manufacturer's experience in the industry. A reputable manufacturer should have a proven track record and extensive knowledge of MS pipe production processes. This experience is often reflected in the quality of the machines and the innovative features they offer.

Another important aspect to consider is the level of customization available. Different projects may require unique specifications, and the ability to tailor the machine to meet these needs is crucial. Look for manufacturers that offer a range of customization options, including size, design, and functionality. This flexibility can significantly impact the efficiency and output of your production line.

Tips: Always ask for references or case studies from previous clients to gauge the manufacturer's reliability. Additionally, check if the manufacturer provides after-sales support and training, as this can play a pivotal role in the machine's performance and longevity. Finally, consider the warranty and maintenance services offered, as these can save you costs and ensure operational continuity over time.

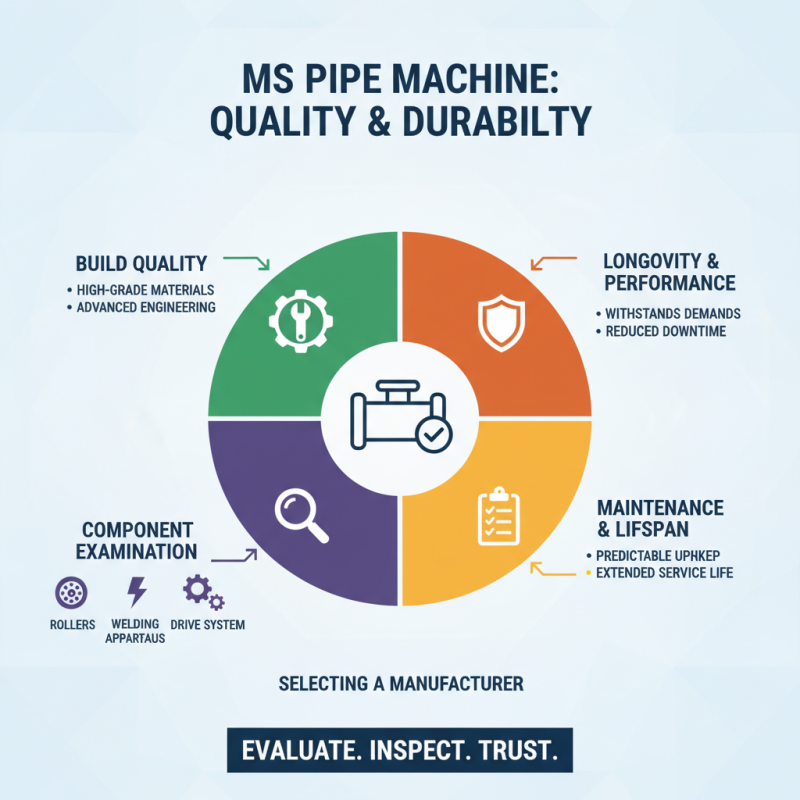

When selecting a manufacturer for MS pipe making machines, evaluating the quality and durability of the machines is paramount. The construction quality of the equipment serves as a crucial indicator of its longevity and performance. Manufacturers that utilize high-grade materials and adopt advanced engineering practices typically produce machines that can withstand rigorous operational demands. A thorough examination of the machinery’s components, such as the drive system, rollers, and welding apparatus, will provide valuable insights into its potential lifespan and maintenance requirements.

Additionally, it is essential to consider the manufacturer's commitment to quality assurance processes. Companies that implement strict quality control measures during production are likely to deliver more reliable machines. Investigating customer feedback and case studies can further illuminate the practical performance of the equipment in real-world applications. Pay attention to aspects such as ease of operation, energy efficiency, and the availability of technical support, as these factors play a significant role in the overall durability and user satisfaction of MS pipe making machines. By carefully assessing these elements, businesses can make informed decisions that enhance operational efficiency and minimize downtime.

The landscape of MS pipe production is rapidly evolving, driven by significant technological advancements that enhance efficiency, quality, and sustainability. One of the most noteworthy developments is the adoption of automated manufacturing processes. These technologies leverage robotics and AI-powered systems to streamline production lines, reducing human error and increasing output. Automation not only improves precision in the shaping and welding of pipes but also enables manufacturers to better control the quality of their products through enhanced monitoring and analytics.

Furthermore, innovations in materials science have resulted in the development of new alloys and coatings that improve the durability and corrosion resistance of MS pipes. These advancements not only extend the lifespan of the products but also minimize maintenance costs for users. In addition, the incorporation of environmentally friendly practices through advanced filtration systems and energy-efficient machinery is becoming a standard in manufacturing facilities. This shift ensures that the production of MS pipes aligns with global sustainability goals while also meeting the increasing demand for high-quality piping solutions in various industries.

When selecting the best MS pipe making machine manufacturers,

customer support and service should be a major consideration. A manufacturer that

prioritizes excellent customer support demonstrates

a commitment to building long-term relationships with their clients. This can include

providing thorough pre-sale consultations, addressing specific needs, and offering expert

advice on machine specifications that align with production goals. By evaluating the

responsiveness and accessibility of customer service representatives, potential buyers can

gauge how effectively a manufacturer is prepared to assist them during the selection

and purchasing process.

In addition to pre-sale support, ongoing service is crucial for ensuring that machinery

operates efficiently over time. Manufacturers that provide reliable maintenance support,

readily available spare parts, and knowledgeable technical service contribute significantly

to reducing downtime and enhancing productivity. When assessing a manufacturer, inquire

about their after-sales service policies and the availability of training programs for operators.

A robust service framework not only facilitates the proper functioning of equipment but also

empowers clients to maximize their investment, ensuring that they can achieve optimal results

from their MS pipe making machines.

When considering the purchase of MS pipe making machines, examining the pricing models and warranty options is crucial for ensuring a favorable investment. According to a recent industry report by MarketsandMarkets, the global market for pipe manufacturing machinery, valued at approximately $3.5 billion in 2021, is expected to grow at a compound annual growth rate (CAGR) of 4.5% through 2026. This growth underscores a vibrant market where pricing strategies can vary significantly among manufacturers, making it essential for buyers to compare costs thoroughly.

In addition to pricing, warranty options play a vital role in the decision-making process. A comprehensive warranty not only protects your investment but also reflects the manufacturer’s confidence in their equipment. Industry standards indicate that robust warranty plans can range from one to five years, with some manufacturers also offering extended service agreements. These warranties often cover parts and labor, making them an essential consideration, particularly for heavy-use machinery, which might experience wear and tear over time. A study by IBISWorld reveals that manufacturers who provide longer warranty periods typically see increased customer satisfaction and loyalty, indicating that a good warranty should factor heavily into purchasing decisions.