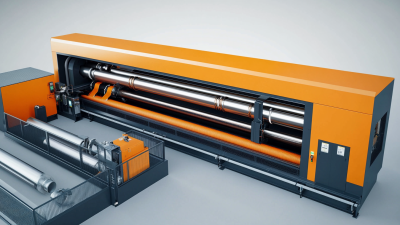

In today's increasingly interconnected global market, sourcing high quality pipe machine equipment presents a myriad of challenges for buyers. With the rise of international trade, companies face significant hurdles in navigating differing standards, regulations, and quality assurance practices across various countries. The quest for high quality pipe machine equipment often leads to additional complications such as communication barriers, cultural differences, and the risk of counterfeit products infiltrating the supply chain. Furthermore, fluctuating currency rates and geopolitical factors can add layers of unpredictability to procurement processes. In this blog, we will explore the multifaceted challenges global buyers encounter when sourcing high quality pipe machine equipment, shedding light on the critical reasons behind these difficulties and offering insights into how companies can effectively manage them.

Sourcing high-quality pipe machine equipment poses significant challenges for global buyers, particularly in navigating the complexities of the international market. Recent insights suggest that buyers must leverage procurement advantages and innovate strategies to optimize projects effectively, particularly in light of the rapid market growth in related sectors. For instance, the gas stove market is projected to expand from $116.22 billion in 2025 to $234.64 billion by 2033, reflecting a compound annual growth rate (CAGR) of 9.18%. This trend underlines the necessity for pipe machine equipment suppliers to maintain high standards and adapt swiftly to evolving demands.

To navigate these challenges, buyers should focus on three key strategies. First, establishing robust relationships with suppliers can enhance communication and streamline the procurement process, ensuring that both quality and timelines are met. Second, staying informed about emerging technologies and market trends, such as the anticipated surge in hydrogen energy utilization—expected to satisfy 18% of global energy demand by 2050—can help buyers make strategic decisions. Lastly, continuous assessment of market conditions and economic forecasts will empower buyers to anticipate shifts in demand, enabling them to adjust sourcing strategies proactively.

Understanding the variability in quality standards for pipe machine equipment is crucial for global buyers. One of the primary challenges they face is the lack of a unified set of specifications. Different regions often have distinct manufacturing regulations and quality benchmarks, which can lead to confusion and inconsistency in product offerings. For instance, equipment that meets European standards may not comply with the regulations set forth in Asia or North America, resulting in complications during procurement and installation.

Understanding the variability in quality standards for pipe machine equipment is crucial for global buyers. One of the primary challenges they face is the lack of a unified set of specifications. Different regions often have distinct manufacturing regulations and quality benchmarks, which can lead to confusion and inconsistency in product offerings. For instance, equipment that meets European standards may not comply with the regulations set forth in Asia or North America, resulting in complications during procurement and installation.

Moreover, the variability in material quality and manufacturing processes can affect the overall performance and longevity of pipe machine equipment. Buyers must be diligent in vetting suppliers and understanding the certification processes that different manufacturers adhere to. This often involves an extensive due diligence process, including on-site inspections and quality assessments, which can be resource-intensive. As a result, global buyers must educate themselves about international standards and invest time in building relationships with reputable suppliers to mitigate the risks associated with sourcing equipment that may not meet their quality expectations.

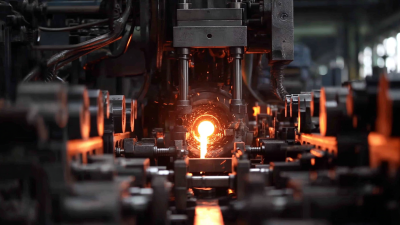

The challenges faced by global buyers in sourcing high-quality pipe machinery are significantly exacerbated by supply chain disruptions. As industries like oil and gas increasingly embrace non-corrosive pipelines, such as thermoplastic types, the need for efficient sourcing becomes more pressing. The rising acceptance of these innovative materials underscores the urgency for manufacturers to adapt and ensure they have reliable access to the best machinery. However, recent disruptions have shown that traditional supply chains can falter, leaving manufacturers scrambling for alternatives.

To combat these challenges, companies are restructuring their supply bases, prioritizing resilience while striving for efficiency. This strategic shift is essential, particularly as industries become more reliant on advanced materials that can enhance operational performance. By integrating machine learning and IoT technologies for better supply chain analytics, companies can optimize their processes, ensuring they remain competitive amid ongoing fluctuations. As the landscape evolves, the focus on maintaining a robust supply chain that can withstand unforeseen disruptions will be crucial for success in sourcing high-quality pipe machinery.

Navigating compliance and regulatory barriers is one of the most significant challenges faced by global buyers when sourcing high-quality pipe machine equipment. Different countries have unique standards and regulations governing the importation of machinery, which can vary widely. Buyers must stay informed about relevant safety standards, environmental regulations, and specific certifications required by their target markets. This necessity for compliance can complicate the procurement process and lead to delays in project timelines if not carefully managed.

Additionally, the complexity of cross-border transactions adds another layer of difficulty. Buyers often encounter various tariffs, taxes, and import duties that can impact the total cost of ownership of the equipment. Engaging with local authorities and understanding the bureaucratic nuances in different regions is crucial for successful sourcing. Furthermore, discrepancies in documentation and compliance requirements can lead to rejected shipments, incurring additional costs and logistical headaches. Thus, global buyers must adopt a proactive approach, leveraging expert knowledge and local partnerships to navigate these regulatory challenges effectively.

This chart illustrates the key challenges that global buyers encounter when sourcing high-quality pipe machine equipment, showing the percentage of buyers affected by each issue.

When sourcing high-quality pipe machine equipment, global buyers must prioritize supplier reliability. In a sector characterized by fierce competition and diverse offerings, evaluating suppliers through key metrics is essential. Factors such as manufacturing capabilities, quality control measures, and delivery performance play a significant role in determining a supplier's reliability. Buyers should assess these elements meticulously to ensure that their chosen supplier can meet the rigorous demands of the industry.

Moreover, transparency and communication are critical indicators of a supplier's dependability. Buyers should look for suppliers who are open about their production processes and willing to share performance data, including defect rates and lead times. Conducting site visits or audits can also provide invaluable insights into a supplier's operations, fostering a stronger partnership built on trust. By carefully analyzing these metrics, global buyers can mitigate risks and secure a reliable supply chain for their pipe machinery needs.

| Metric | Importance Level (1-5) | Average Score of Suppliers | Notes |

|---|---|---|---|

| Product Quality Assurance | 5 | 4.2 | Critical for ensuring high standards. |

| Delivery Reliability | 4 | 3.9 | Timely delivery impacts overall operations. |

| Pricing Competitiveness | 4 | 4.5 | Balance between cost and quality is vital. |

| Technical Support Availability | 5 | 4.0 | Essential for operational troubleshooting. |

| Supplier Experience | 3 | 3.5 | Experience can indicate reliability. |