The Tube Mill Production Line is crucial for producing various tubular products. In industries such as construction and manufacturing, the efficiency and quality of these mills directly impact overall productivity. Choosing the right production line can be challenging, with numerous specifications and options available.

Many factors influence the effectiveness of a Tube Mill Production Line. These include the type of materials used, the machinery's setup, and ongoing maintenance. Buyers often feel overwhelmed by these choices. Understanding which components matter most can help make an informed decision.

It is also vital to consider the latest technological advancements in tube mills. New features can enhance productivity but may require additional training for staff. Potential owners might overlook this important aspect. Reflecting on these factors ensures a better understanding of what makes a Tube Mill Production Line truly efficient.

The tube mill production line is a fascinating area of technology. It enables the manufacturing of high-quality tubes for various applications. These lines are complex systems comprising multiple components.

Modern tube mills use advanced techniques for improved efficiency. They convert flat steel into tubes through various processes. The equipment includes uncoilers, forming stations, and welders. Each step requires precision. A small error can lead to significant production issues. Operators must be vigilant and well-trained.

While the technology is impressive, challenges remain. Maintenance is crucial to keep the production line running smoothly. Neglecting routine checks can result in costly downtime. Additionally, adapting to new materials adds complexity. The industry must remain flexible to meet changing demands. Continuous improvement and innovation are essential for success. It’s a journey that requires constant reflection and adjustment.

When considering the key components of a tube mill production line, two elements stand out: the mill itself and the tooling. The mill's design influences production efficiency. According to industry data, well-optimized mills can achieve up to 90% operating efficiency. This is crucial for reducing downtime and maintaining quality.

Tooling also plays a critical role. High-quality molds can improve the tube's overall structure and durability. Reports indicate that investing in better tooling can decrease scrap rates by nearly 30%. However, some manufacturers overlook this aspect, leading to increased costs and lower production rates.

Tips: Regular maintenance checks are essential. They help to catch issues early, boosting mill performance. Moreover, investing in staff training can enhance operational success. A skilled workforce knows the ins and outs of production lines. Continuous improvement is necessary. Always be open to adjustments based on performance data.

This chart presents the key performance metrics for tube mills in 2026, highlighting capacity, energy consumption, production downtime, and waste rates for optimal production efficiency.

When selecting a tube mill manufacturer, several important factors should be evaluated. First, consider the machinery quality. Look for manufacturers that use robust materials. This ensures durability and long-term performance. It's essential to request samples or visit production sites to inspect their equipment.

Another vital factor is the manufacturer's experience. A company with years in the industry likely understands various production challenges. They often come up with innovative solutions. However, beware of overestimating their capabilities based on years alone. Speak to past clients to gain real insights.

After evaluating quality and experience, think about customer support. Quick responses and reliable service can significantly impact production. You need a partner who supports you, especially when issues arise. Sometimes, hidden costs come up in contracts. Read everything carefully to avoid surprises later on. Choosing the right manufacturer requires thorough research and reflection on your specific needs.

Maintaining tube mill equipment is crucial for optimal performance. Regular inspections can prevent significant breakdowns. Operators should check for wear and tear on various components. This step is often overlooked but can save time and money in the long run.

Tips: Schedule weekly check-ups. Look for loose bolts and misalignments. These issues can escalate if ignored.

Cleaning is vital too. Dust and debris can accumulate in the machinery. Regular cleaning can enhance efficiency and prolong equipment life. Many overlook this routine task. A clean mill operates more smoothly and with less friction.

Tips: Use compressed air to clear out areas. Ensure all parts are accessible during cleaning. This will promote a safer workspace.

Training your staff is essential. Properly trained personnel can detect issues early. They can also adhere to safety protocols. Lack of training leads to poor maintenance practices, which increases downtime. So, continuous staff development is necessary.

Tips: Organize hands-on sessions. Use real-life scenarios for training. Keep a checklist for each operator. This ensures accountability.

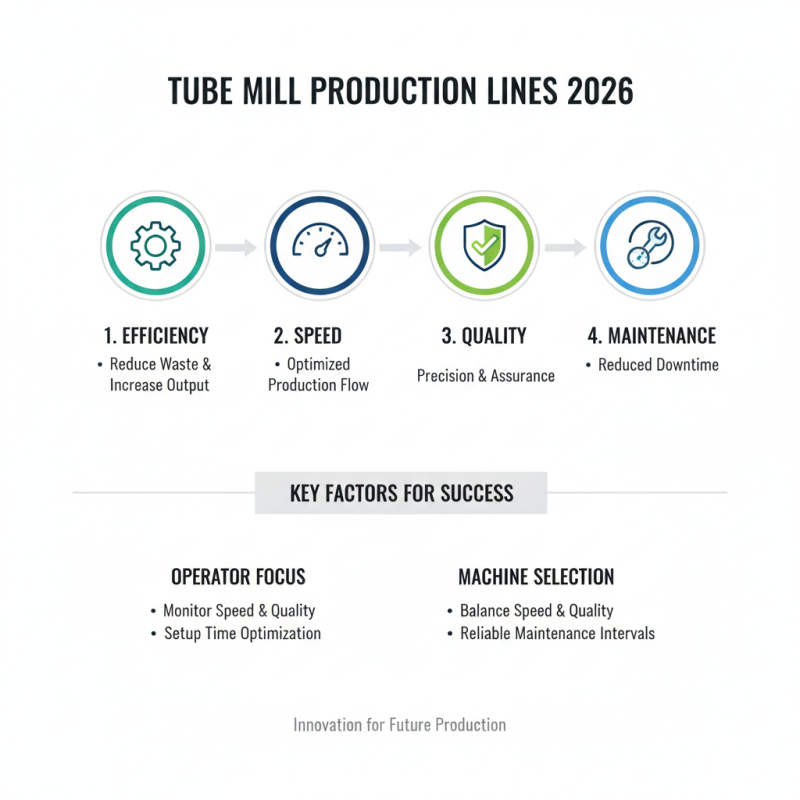

When considering the best tube mill production lines for 2026, several factors come into play. First, the efficiency of the line is crucial. A well-optimized production line can significantly reduce waste and increase output. Operators should look closely at the speed and quality of the machines. Many factors affect performance, including setup time and maintenance intervals. It is vital to choose machines that balance speed with quality assurance.

Another essential aspect is the adaptability of the production line. The industry is ever-evolving, and flexibility is key. Some lines can be adjusted for various tube sizes and materials. This adaptability can save costs in the long run but often requires more initial investment. It's worthwhile to assess trade-offs. Not all production lines are created equal; some may excel in specific areas but fall short in others.

Operator training cannot be overlooked. Well-trained staff can mitigate many of the issues that arise in tube production, such as defects and downtime. However, training programs are often underfunded and neglected. Reflecting on training might lead to more streamlined operations and better product quality. Remember, a great production line is only as good as the team operating it.