In today’s industrial landscape, efficiency is crucial. The Tube Mill Pipe Making Machine offers an effective solution for producing high-quality pipes. From raw materials to finished products, this machine enhances production speed and quality.

Manufacturers face challenges in selecting the right equipment. The performance of a Tube Mill Pipe Making Machine can vary significantly. Some machines struggle with consistency, leading to defects. Investing in the best machines is essential for long-term success.

Additionally, proper maintenance is often overlooked. Regular upkeep ensures optimal performance and prevents costly downtime. As industries evolve, adapting technology becomes fundamental. The right Tube Mill Pipe Making Machine can set a company apart in a competitive market.

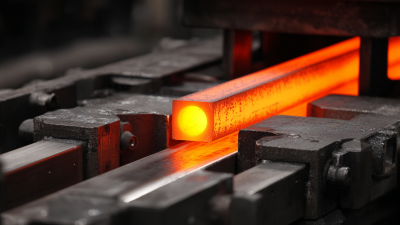

In the world of manufacturing, tube mill pipe making machines play a crucial role. Different types exist, each tailored for specific needs. Some machines are designed for high-speed production, producing seamless tubes efficiently. Others focus on smaller batches, ideal for custom projects.

A common type is the high-frequency welded pipe mill. It offers good speed and efficiency but may require regular maintenance. Some manufacturers prefer spiral pipe mills. These machines are versatile and can produce larger diameter pipes. However, they may involve longer setup times, which can reduce overall productivity.

Operators should also consider their energy consumption. Some machines are energy-intensive, raising operational costs. Ensuring that production aligns with demand is essential. An inline inspection system can minimize waste, yet integrating it can be complex. Balancing efficiency and quality is key in selecting the right machine.

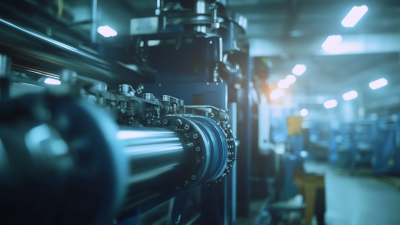

When considering tube mill pipe making machines, efficiency is key. High-performance machines have several features that enhance production. Speed is crucial; faster processing times lead to increased output. Strong motors and advanced technology allow for quicker adjustments and operations.

Another essential aspect is durability. Machines built with robust materials resist wear and tear. This reliability reduces downtime for maintenance. Ergonomic designs also matter, making it easier for operators to work efficiently. Adjustable settings can accommodate different tube sizes without losing quality.

Yet, not every machine performs flawlessly. Some may require frequent recalibrations. Others may not suit all production needs. Investment in high-quality machines can be significant, but the returns in efficiency can justify the cost. Balancing cost with performance is crucial for long-term success.

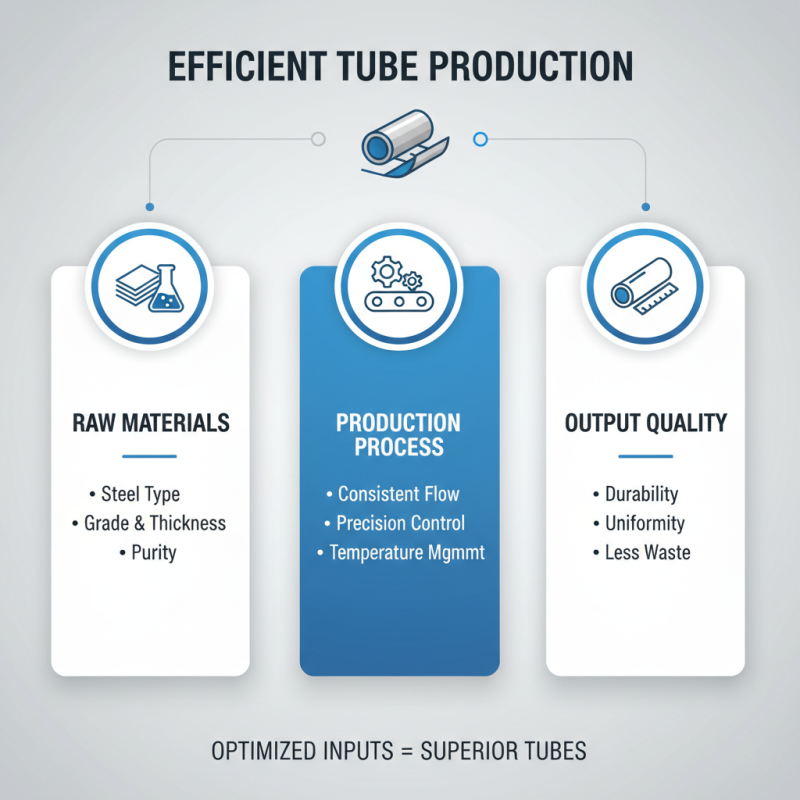

Efficient tube production relies on various factors that can significantly enhance output quality. The choice of raw materials plays a vital role. The thickness and grade of the steel influence the durability of the final product. A careful assessment of these materials ensures that the production process remains consistent.

Machine settings also determine the efficiency of making tubes. Speed, pressure, and temperature must all align perfectly. If one element is off, it can lead to defects in the tubes. Regular calibration and maintenance are essential to maintain optimal operations.

Additionally, skilled operators are crucial to achieving high efficiency. Training and experience help workers adapt to challenges in the production line. Mistakes can happen, but learning from them leads to better processes. A team that communicates well can solve issues promptly. Efficient tube production is a blend of technology and human skill, each influencing the final outcome.

Maintaining a tube mill is crucial for achieving optimal performance. Regular inspections help identify wear and tear. A detailed check of the bearings, rollers, and welding heads can prevent costly breakdowns. Look for signs of overheating or unusual noise. These are early warnings indicating issues.

Cleaning components regularly is essential. Dust and metal shavings accumulate during production. Neglecting this buildup can lead to diminished efficiency. Consider a maintenance schedule that includes daily, weekly, and monthly tasks. Create checklists to ensure no area is overlooked.

Unexpected problems happen. Sometimes, a machine may behave strangely. Operators should be trained to troubleshoot basic issues. Document any irregularities for future reference. This creates a knowledge base for the team, improving response times. Reflecting on past maintenance experiences can enhance future practices.

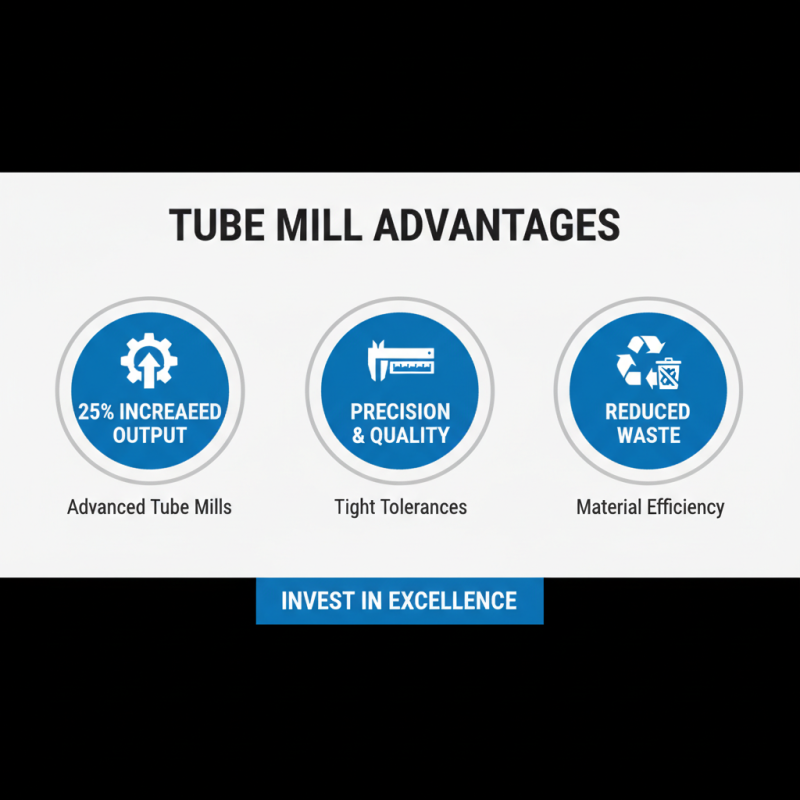

Investing in a high-quality tube mill machine can significantly enhance production efficiency. According to a recent industry report, companies using advanced tube mills reported a 25% increase in output. The precision of these machines ensures that products meet tight tolerances. This reduces waste and improves product quality.

A quality tube mill can lower operational costs in the long run. Some industries face up to 20% of total costs due to machine downtime. Efficient tube mills minimize these interruptions. Enhanced automation features contribute to smoother operations. However, initial investments can be challenging for some businesses.

Durability is another vital aspect. Machines made from robust materials often last longer. Reports show that durable machines can operate effectively for over a decade with proper maintenance. Still, not all machines live up to expectations. It’s crucial to analyze performance metrics. Investing in a quality machine is a decision that requires careful consideration.