In the ever-evolving landscape of the manufacturing industry, the demand for efficient and reliable welding solutions has never been more critical. High Frequency Pipe Welding Machines have emerged as a pivotal technology, providing unparalleled precision and speed in pipe welding applications. According to a report by MarketsandMarkets, the global welding equipment market is projected to reach $26 billion by 2025, with high frequency welding technologies driving significant growth due to their ability to enhance productivity and reduce costs. These machines utilize high frequency currents to achieve fast and robust welds, making them ideal for industries such as construction, automotive, and energy.

Moreover, a study from Research and Markets indicates that advancements in welding technology, including automation and digital integration, are revolutionizing traditional welding processes. High Frequency Pipe Welding Machines are at the forefront of this transformation, facilitating superior weld quality while minimizing heat distortion and energy consumption. As the industry adapts to increasingly stringent quality standards and eco-friendly practices, investing in high frequency welding solutions will not only improve operational efficiency but also align with sustainability initiatives. In light of these trends, we present a comprehensive overview of the 10 best High Frequency Pipe Welding Machines available today, designed to enhance productivity and meet the growing demands of modern manufacturing.

High-frequency welding machines have gained traction in various industries due to their efficiency and precision. As we look ahead to 2025, the market for these machines is expected to expand significantly. Recent reports indicate a notable rise in the demand for welding systems, particularly those utilizing advanced technologies like ultrasonic and laser welding. This trend reflects a broader interest in automation and energy efficiency within manufacturing processes, emphasizing the need for upgraded equipment that integrates modern technology.

High-frequency welding machines have gained traction in various industries due to their efficiency and precision. As we look ahead to 2025, the market for these machines is expected to expand significantly. Recent reports indicate a notable rise in the demand for welding systems, particularly those utilizing advanced technologies like ultrasonic and laser welding. This trend reflects a broader interest in automation and energy efficiency within manufacturing processes, emphasizing the need for upgraded equipment that integrates modern technology.

When considering high-frequency welding machines, it's crucial to assess the specific needs of your operation. Tip: Choose machines with adjustable frequency settings to accommodate different materials and thicknesses effectively. Additionally, prioritize models that come equipped with advanced monitoring features to ensure consistent weld quality. Tip: It’s beneficial to evaluate customer feedback and performance reviews when selecting a machine, as real-world usage often reveals insights that specifications alone cannot provide. Investing in high-quality welding equipment can lead to significant improvements in production efficiency and product quality.

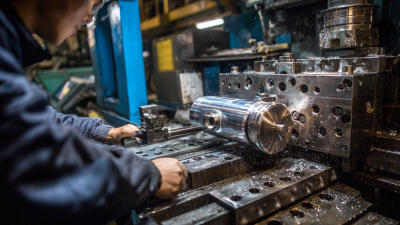

When choosing a high frequency pipe welder, several key features should be taken into account to ensure efficient and effective welding. Firstly, the power output of the machine is crucial; it directly affects the quality and speed of the welding process. High frequency welders typically offer a range of power settings, enabling users to select the appropriate output based on the thickness and type of the materials being welded. Additionally, checking for inverter technology is essential, as this feature enhances stability and efficiency in energy consumption, leading to better weld quality and reduced operational costs.

Another important aspect to consider is the machine's ease of use, which can be significantly influenced by its interface and controls. User-friendly controls allow operators to make quick adjustments during the welding process, enhancing productivity. Furthermore, portability is a significant consideration, especially for jobs that require maneuverability on-site. Lightweight machines with sturdy construction are ideal, as they can withstand the rigors of transport while still delivering high performance. Finally, ensure that the machine is equipped with essential safety features, such as overload protectors and cooling systems, to safeguard both the equipment and operators during intensive welding tasks.

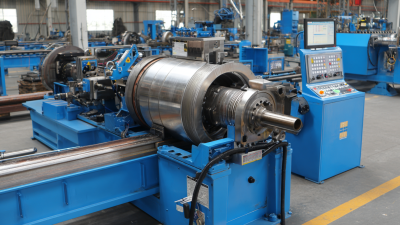

When evaluating the top high frequency pipe welding machines, several key factors come into play that can significantly impact the efficiency and quality of welding. These machines are specially designed to provide precise control over the heating process, which is crucial for achieving strong welds while minimizing material distortion. The comparative analysis reveals variations in output power, frequency range, and duty cycle among the top contenders, allowing users to find a machine that best fits their specific needs.

Furthermore, user friendliness and technological features play an important role in the selection process. Advanced digital controls, real-time monitoring, and automated settings can enhance the overall welding experience. Additionally, factors such as portability, durability, and after-sales support should also be examined when choosing a high frequency welding machine.

This analysis not only highlights performance metrics but also addresses the adaptability of each machine for various types of projects, ensuring users can make informed decisions based on their operational requirements.

In 2025, the market for high-frequency pipe welding machines has seen substantial advancements, with user reviews highlighting key models known for their performance and efficiency. Among the top-rated machines, users frequently mention features such as robust design, ease of use, and exceptional welding speed. These models have garnered positive feedback for their ability to deliver precise welds, making them ideal for both industrial applications and small-scale projects.

When selecting a high-frequency pipe welding machine, keep in mind a few essential tips. First, consider the power output and frequency range, as these factors directly impact welding quality and speed. Additionally, look for machines equipped with user-friendly interfaces and digital displays that simplify operation, particularly for those new to welding. Lastly, check for warranty and customer support options; reliable after-sales service can be crucial in maintaining machine performance over time.

Overall, understanding user experiences and performance ratings helps in making informed decisions about which high-frequency pipe welding machine to invest in. The right choice not only boosts productivity but also enhances the quality of welded joints, ensuring long-lasting results in your projects.

The landscape of high-frequency welding is being transformed by innovative technologies that not only enhance welding precision but also support sustainable industrial practices. Recent advancements leverage methodologies like bead-to-bead analysis, enabling accelerated quantitative assessments of welding behaviors. This results in the production of lightweight components vital for a sustainable future across various sectors. As industries evolve, skilling freshers in advanced welding techniques ensures that the workforce is equipped to drive innovation and precision.

According to the latest market analysis, the stainless steel welded pipe market is projected to reach USD 34.0 billion by 2035, indicating a robust 5.0% CAGR from 2025 onwards. This growth reflects the increasing demand for advanced welding techniques and materials that meet modern engineering standards. Innovative rail welding technologies are also on the rise, developed to double weld lifespans and bolster railway infrastructure safety in the U.S., showcasing the need for continual advancements in the field.

**Tips:** Invest in training programs that focus on the latest welding technologies to future-proof your workforce. Embrace methodologies that enhance the efficiency of welding processes, ensuring your operations meet the demands of a rapidly advancing market. Consider integrating automated welding solutions to address the growing skills gap in industries like civil engineering.

| Model | Power Output (kW) | Frequency (kHz) | Welding Thickness (mm) | Weight (kg) | Price (USD) |

|---|---|---|---|---|---|

| Model A | 20 | 50 | 5 | 150 | 3000 |

| Model B | 25 | 60 | 8 | 160 | 4000 |

| Model C | 30 | 70 | 10 | 180 | 5000 |

| Model D | 35 | 80 | 12 | 200 | 6000 |

| Model E | 40 | 90 | 15 | 220 | 7000 |