In the rapidly evolving landscape of manufacturing, the adoption of advanced machinery has become crucial for maintaining competitiveness and efficiency. Among these innovations, the Square Tube Mill Pipe Making Machinery stands out as a transformative tool for fabricating durable and reliable square tubing. As industries continue to seek cost-effective solutions while ensuring high-quality output, the significance of utilizing such machinery will only grow in 2025 and beyond.

The Square Tube Mill Pipe Making Machinery offers numerous benefits, including enhanced production speed, precision, and versatility. This machinery facilitates the seamless transformation of raw materials into finished products, significantly reducing labor costs and minimizing waste. Companies that invest in this technology can adapt more swiftly to changing market demands, ensuring they stay ahead of the competition.

Furthermore, the evolving trends in construction and manufacturing industries highlight the increasing need for efficient and versatile solutions. By leveraging the capabilities of Square Tube Mill Pipe Making Machinery, businesses not only improve their operational efficiencies but also contribute to sustainable practices through optimized resource usage. As we look to the future, embracing these advanced manufacturing technologies will be essential for success in the increasingly competitive marketplace.

The advantages of square tube mill pipe making machinery are becoming increasingly pronounced in modern manufacturing settings as we move further into 2025. One significant benefit is the machinery's capacity to produce uniform and precise dimensions, which is critical for industries such as construction, automotive, and aerospace. According to a recent industry report by Market Research Future, the demand for square tubes is projected to grow at a CAGR of 4.8% through 2025, highlighting the essential role of efficient manufacturing processes in meeting this demand.

Additionally, square tube mill machinery enhances operational efficiency. With advancements in automation and technology, these machines can produce large quantities of square tubes with minimal labor. A study published by the Fabricators & Manufacturers Association noted that companies utilizing modern pipe making machinery saw production increases of up to 30%. This not only improves profitability but also allows manufacturers to respond quickly to market changes.

Tips: To maximize the benefits of square tube mill machinery, companies should invest in regular maintenance and operator training. Ensuring that operators are well-versed in the latest technologies and maintenance practices can significantly reduce downtime and enhance production output. Furthermore, integrating data analytics into the manufacturing process can help identify trends and inefficiencies, allowing for proactive adjustments that improve overall productivity and quality.

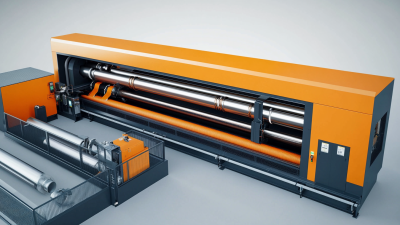

The adoption of square tube mill pipe making machinery in 2025 promises to revolutionize production processes across various industries. One of the standout benefits of these advanced machines is their ability to significantly enhance productivity. By streamlining the pipe manufacturing process, square tube mills facilitate faster processing times, allowing manufacturers to produce more units in a shorter timeframe. This is particularly crucial in industries that demand high-volume output and quick turnaround times, where efficiency can directly correlate to profitability.

Moreover, the precision engineering behind square tube mills ensures a higher level of consistency and quality in production. These machines are designed to minimize material waste and reduce operational downtime, which not only leads to cost savings but also contributes to more sustainable manufacturing practices. Enhanced production efficiency translates to better resource management, allowing companies to allocate their resources more effectively. As a result, businesses can meet customer demands promptly while maintaining the integrity of their product quality, ultimately strengthening their competitive edge in the market.

The chart illustrates the potential productivity benefits of using square tube mill pipe making machinery in 2025. Analyzing the data reveals that increased speed contributes the most to productivity, followed by cost reduction and improved precision. Lower waste and higher flexibility are also significant, showcasing the overall efficiency improvements that square tube mills can bring to production processes.

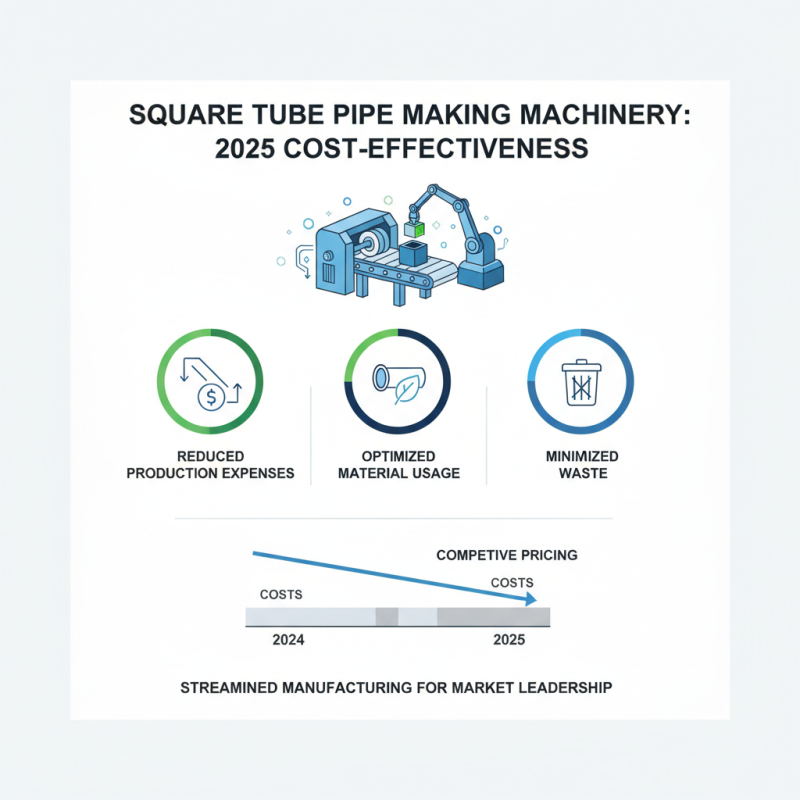

When considering the cost-effectiveness of square tube pipe making machinery in 2025, businesses are likely to experience significant reductions in production expenses. These innovative machines are engineered to streamline the manufacturing process, optimizing material usage and minimizing waste. By efficiently transforming raw materials into finished products, companies can reduce their overall costs and maintain competitive pricing in the market.

Tips to enhance cost-effectiveness include regular maintenance of machinery to ensure longevity and performance. Implementing a preventive maintenance schedule can help identify potential issues early, avoiding costly repairs or downtime. Additionally, investing in staff training on best practices for operating the machinery can increase productivity and reduce errors, further contributing to cost savings.

Another pivotal aspect is the selection of quality materials that complement the capabilities of the machinery. By sourcing high-grade materials at competitive prices, manufacturers can enhance their output quality while still benefiting from cost efficiencies. Balancing quality with cost will not only lead to better products but also strengthen the brand's reputation in a crowded market.

The utilization of square tube mill pipe making machinery is increasingly recognized for its pivotal role in maintaining quality control within manufacturing processes. By integrating advanced technology, manufacturers can achieve consistent dimensions and mechanical properties in square tubing. According to a report from the International Association of Metal Manufacturers, incorporating automated quality checks throughout the production line can reduce defects by up to 30%, ultimately leading to higher customer satisfaction and reduced waste.

Tips for ensuring quality control include implementing real-time monitoring systems that track the dimensions and thickness of the tubes as they are produced. This proactive approach helps to identify deviations early in the process, allowing for immediate adjustments. Additionally, regular calibration of machinery ensures that the equipment operates within optimal parameters, further enhancing product consistency.

Leveraging data analytics is another effective strategy. Analyzing production data can help manufacturers identify patterns and potential issues before they escalate. Reports indicate that companies employing data-driven decision-making processes have seen a 20% increase in efficiency and a significant decrease in rework rates. By prioritizing these practices, manufacturers can ensure that their square tube products meet the stringent quality standards demanded by the market.

The advancement of pipe making machinery, particularly in 2025, has ushered in a new era of environmentally conscious manufacturing. One of the primary benefits of utilizing advanced square tube mill pipe making machinery lies in its energy efficiency. Modern equipment is designed with enhanced technology that minimizes energy consumption during production. By reducing the overall energy footprint, manufacturers contribute to lower greenhouse gas emissions, positioning themselves as more sustainable players in the industry.

Additionally, these innovative machines often incorporate eco-friendly materials and processes. For instance, advancements in materials science have led to the development of recycled and recyclable components in machinery. This not only lessens the demand for virgin materials but also encourages a circular economy within the manufacturing sector. Furthermore, with automated features, operators can achieve optimal performance while minimizing waste, leading to less scrap and a lower environmental impact throughout the production cycle. As sustainability becomes a focal point for industries globally, the role of advanced pipe making machinery will be pivotal in achieving these essential environmental goals.

| Benefit | Description | Impact | Year Achieved |

|---|---|---|---|

| Reduced Waste | Minimization of material waste through optimized manufacturing processes. | Up to 30% reduction in waste materials. | 2025 |

| Energy Efficiency | Advanced technology reduces energy consumption during production. | Energy savings of approximately 40%. | 2025 |

| Lower Carbon Footprint | Using renewable energy sources in the production line. | Significant reduction in CO2 emissions. | 2025 |

| Sustainable Materials | Utilization of recycled materials for pipe manufacturing. | Increased use of 50% recycled materials. | 2025 |

| Improved Product Quality | Higher precision and consistency in product manufacturing. | Boost in customer satisfaction and less product failure. | 2025 |