In the world of manufacturing, efficiency is key. The Carbon Steel Tube Mill Pipe Making Machine plays a crucial role in this sector. It offers numerous benefits that enhance production and reduce costs. Businesses seek reliable machinery that aids their operations.

One major advantage of the Carbon Steel Tube Mill Pipe Making Machine is its ability to produce high-quality pipes. This ensures customer satisfaction and builds trust. Moreover, it can operate at high speeds. Faster production times lead to increased outputs, which can boost profits.

Investing in such machinery can lead to initial hesitations. Organizations must consider the upfront costs. However, the long-term benefits often outweigh these concerns. The quality of the pipes produced can significantly impact project success. Ultimately, choosing the right equipment is vital for any company looking to grow and adapt in a competitive market.

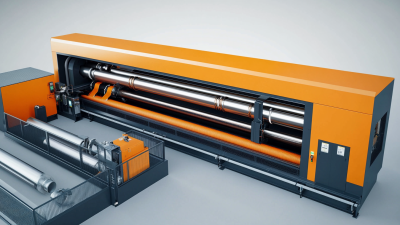

Carbon steel tube mill pipe making machines offer numerous advantages for manufacturers in various industries. These machines are known for their efficiency and speed. They can produce high-quality tubes with precise dimensions, reducing waste and ensuring consistency. According to a recent industry report, carbon steel pipes account for over 60% of the global pipe market due to their strength and durability.

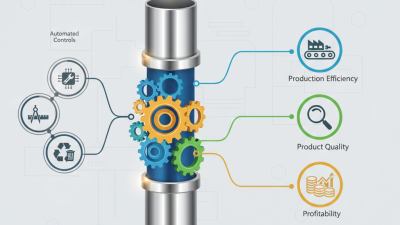

The automation facilitated by these machines streamlines operations. Operators can set parameters with ease, leading to faster production times. However, a lack of skilled personnel can hinder full utilization of these machines, resulting in operational inefficiencies. Moreover, while maintenance is straightforward, ignoring routine checks may lead to costly downtimes, affecting overall productivity.

Flexibility is another key benefit. Carbon steel tube mills can produce a variety of pipe sizes. This versatility allows manufacturers to meet different market demands quickly. Yet, the initial investment can be daunting. It's crucial for businesses to weigh the costs against potential long-term savings. Focusing on these machines can boost competitiveness in a tight market, but it's vital to ensure that proper training and maintenance protocols are in place.

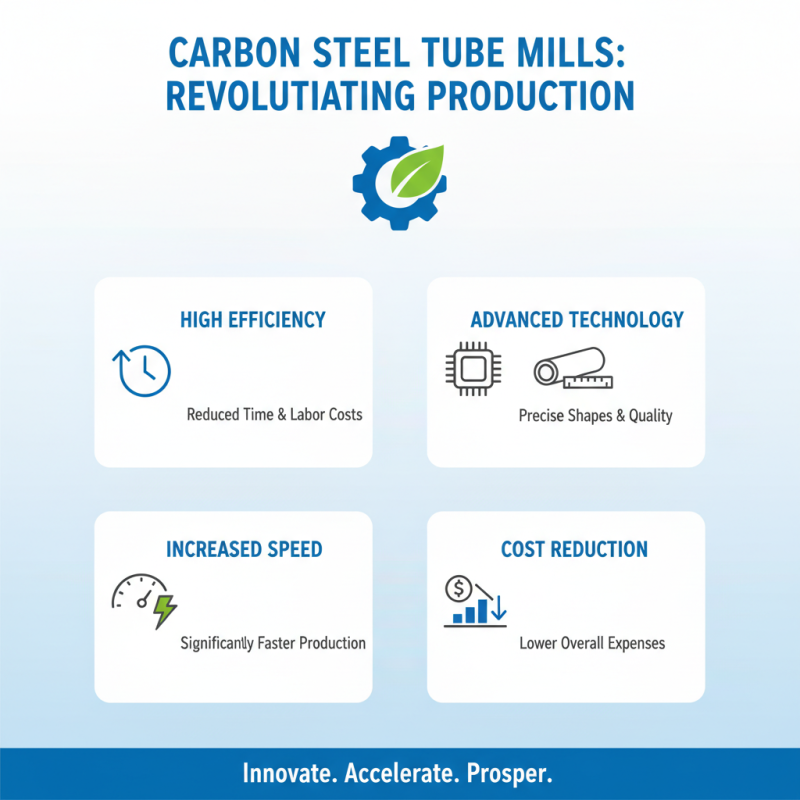

Carbon steel tube mills are revolutionizing the production landscape. They offer high efficiency, reducing time and labor costs. These mills utilize advanced technology to create precise shapes. The speed of production can increase significantly, leading to reduced overall expenses.

In today's competitive market, every second counts. Carbon steel tube mills help manufacturers meet tight deadlines. The ability to produce high volumes quickly is a game changer. Additionally, the automation in these machines minimizes human error. However, reliance on technology can sometimes lead to unexpected breakdowns.

Durability is another notable aspect of carbon steel tubes. They withstand various stressors, making them ideal for many applications. However, the initial investment can be high, and not every business can afford it. Maintenance is crucial; regular checks can prevent costly repairs. Balancing efficiency with potential downtime is a challenge that requires ongoing attention.

The manufacturing of carbon steel pipes has gained significant attention due to its cost-saving advantages. Industries that rely on these pipes often see reduced expenses over time. The initial investment in a carbon steel tube mill may seem high, but the savings quickly accumulate. This is largely due to lower material costs and increased efficiency in production.

In addition to savings, the durability of carbon steel enhances its appeal. Pipes made from this material can withstand high pressure and extreme temperatures. While they require more power during manufacturing, the overall longevity reduces maintenance costs.

However, not every machine on the market maximizes efficiency. Some may struggle with energy consumption. This can negate the initial savings, requiring careful selection of equipment.

The ability to recycle scrap metal also plays a role in cost savings. When manufacturers utilize recycled materials, they further reduce their production expenses.

Yet, this advantage isn't universal. Many companies overlook the importance of sourcing quality recycled inputs. Ultimately, finding the right balance between cost and quality is crucial. It requires ongoing assessment and adaptation to the ever-evolving market demands.

Carbon steel tubes have gained immense popularity in various industries due to their enhanced durability and strength. The process of manufacturing these tubes involves using advanced carbon steel tube mill pipe making machines, which significantly improve product quality. According to industry reports, carbon steel typically exhibits tensile strengths ranging from 400 to 800 MPa. This makes it ideal for applications requiring both toughness and rigidity.

One of the key benefits of these machines is their precision in controlling the physical properties of the tubes. Enhanced durability comes from the uniform wall thickness achieved during the manufacturing process. Inconsistent wall thickness can lead to weak points, which might fail under pressure. Studies indicate that uniformity can improve overall performance by 20-30%. The ability to produce tubes with optimal strength directly correlates to the efficiency of these machines.

However, manufacturers must pay attention to the machine's settings. Poor calibration can lead to defects, reducing product reliability. A recent quality assessment showed that around 15% of carbon steel tubes fail industry standards. This highlights the need for careful monitoring and adjustments during production. Proper training and frequent machinery maintenance can help mitigate these issues, ensuring tubes maintain their durability and strength.

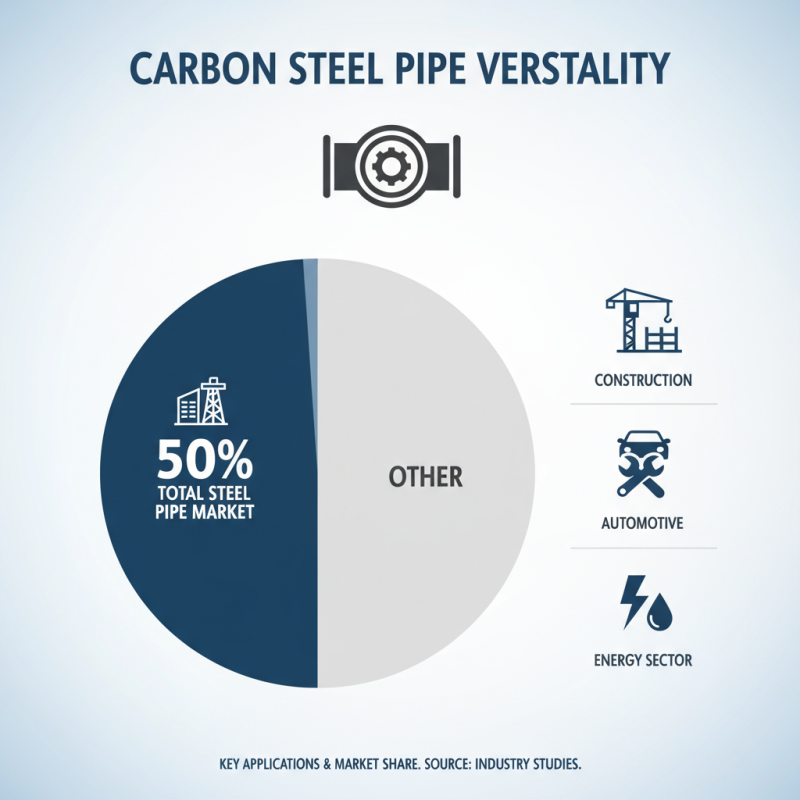

Carbon steel pipe products are incredibly versatile. They find applications in various sectors, including construction, automotive, and energy. According to recent industry studies, carbon steel pipes account for about 50% of the total steel pipe market. This highlights their significance in structural applications.

One reason for this versatility is carbon steel's strength. It can withstand high pressure and temperature changes. This is crucial for industries like oil and gas. In fact, the oil and gas sector uses about 40% of all carbon steel pipes produced. Their ability to withstand harsh conditions makes them ideal for offshore drilling and pipeline construction.

Moreover, carbon steel pipes are often more cost-effective than alternatives. They offer a balance between durability and price. Recent reports indicate that the demand for carbon steel will grow by 5% annually in the coming years. However, the industry faces challenges, such as fluctuating raw material prices. This fluctuation raises questions about long-term sustainability. Overall, the future of carbon steel pipes looks bright, but continuous adaptation is essential.