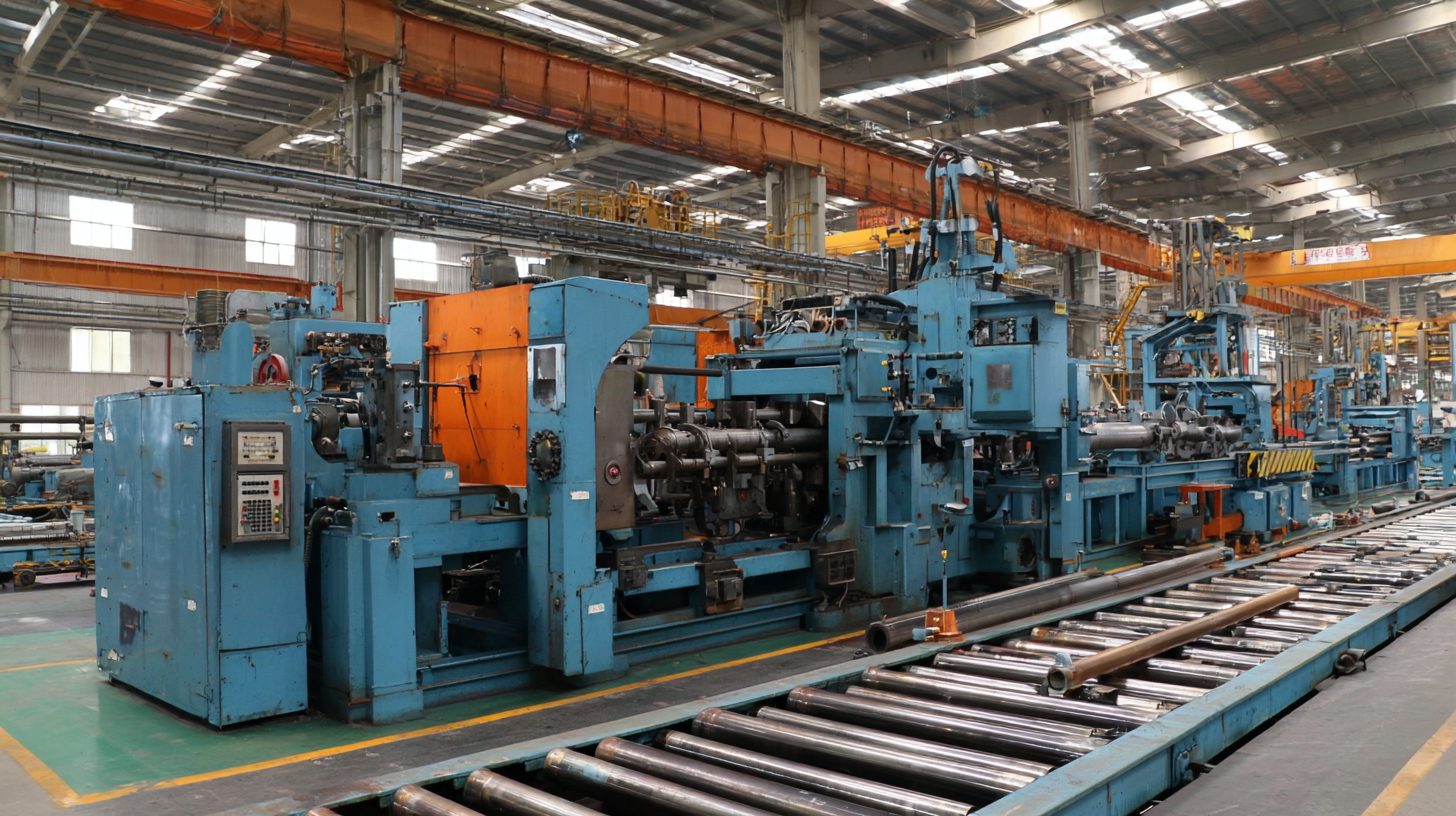

In the ever-evolving landscape of manufacturing, the role of advanced technology cannot be overstated, especially when it comes to enhancing productivity and efficiency. Among the notable innovations is the Industrial Automation Carbon Steel Pipe Making Machine, a cornerstone in the production processes of various industries. As per a recent report by MarketsandMarkets, the global industrial automation market is projected to reach USD 500 billion by 2025, with a significant share driven by the demand for high-quality carbon steel pipes in construction and infrastructure projects. This machine not only improves production speed but also ensures precision and durability in the pipes manufactured. With China's commitment to being a leader in manufacturing excellence, the adoption of such advanced machinery aligns perfectly with its goal of enhancing export capabilities and cementing its status as a powerhouse in the industrial sector.

In the realm of industrial automation, high-efficiency carbon steel pipe making machines stand out as a cornerstone for modern production processes. These machines not only enhance manufacturing speed but also significantly improve quality consistency. By integrating advanced automation technologies, manufacturers can witness a drastic reduction in labor costs and human error, leading to a more streamlined operation that meets the ever-increasing demand for carbon steel pipes.

One of the key advantages of these machines is their ability to optimize energy consumption. Users can expect lower operational costs due to the efficient use of resources and reduced waste during production. Additionally, modern machines come equipped with smart monitoring systems that provide real-time data, enabling quick adjustments and predictive maintenance.

**Tips**: When selecting a carbon steel pipe making machine, look for models that offer customizable settings to cater to specific production needs. Also, invest in training for your operational staff to maximize the benefits of these high-efficiency machines, ensuring that your production capabilities are fully realized.

When selecting the best industrial automation carbon steel pipe making machine, several key features should be prioritized to maximize efficiency and product quality. First and foremost, look for advanced automation capabilities that can streamline the production process. Machines equipped with programmable logic controllers (PLCs) allow for precise control over various parameters, ensuring consistent pipe dimensions and minimal waste. Additionally, an integrated feedback system can monitor operations in real-time, enabling quick adjustments to maintain optimal performance.

Another crucial feature is durability and material quality. The best pipe making equipment should be constructed from high-grade components that can withstand rigorous manufacturing conditions. A robust frame and reliable bearings are essential for reducing downtime and maintenance costs. Furthermore, energy efficiency is an important consideration; machines designed with energy-saving technologies can significantly lower operational costs while reducing environmental impact. By focusing on these features, manufacturers can invest in pipe making machines that not only enhance productivity but also contribute to long-term sustainability and cost-effectiveness.

The evolution of industrial automation has drastically transformed pipe manufacturing processes, particularly with the advent of advanced carbon steel pipe making machines. According to a report by MarketsandMarkets, the industrial automation market is projected to reach $296.7 billion by 2026, emphasizing the growing significance of cutting-edge technology in enhancing production efficiency. These machines integrate features such as real-time data monitoring and automated quality control, which not only speed up production but also significantly reduce the chances of human error.

One important tip for manufacturers looking to upgrade their equipment is to invest in machines that incorporate AI-driven analytics. This technology allows for predictive maintenance, minimizing downtime by identifying potential issues before they become critical. Additionally, using machinery that supports Industry 4.0 frameworks can streamline operations, allowing for seamless integration of the supply chain.

Furthermore, implementing automated systems can lead to cost savings in the long run. According to a study by the International Society of Automation, companies that adopt automation can reduce operational costs by up to 30%. This not only boosts profitability but also increases the competitive edge in an ever-evolving market. Adopting these technologies will be crucial for manufacturers aiming to thrive in today's fast-paced industrial landscape.

| Feature | Description | Benefit | Impact on Production Efficiency |

|---|---|---|---|

| High Automation | Automatic feeding, cutting, and welding processes. | Reduces manual labor and human error. | Increases output rate and consistency. |

| Advanced Control Systems | Incorporates PLC and sensors for precision. | Enhances monitoring and control of processes. | Minimizes downtime and waste. |

| Energy Efficiency | Utilizes energy-efficient technologies. | Lowers operational costs. | Enhances profitability through cost savings. |

| Modular Design | Flexible and scalable configurations. | Adapts to varying production needs. | Optimizes resource allocation and space. |

| Data Analytics | Collects and analyzes production data. | Informs decision-making for improvements. | Facilitates proactive maintenance and upgrades. |

Investing in high-quality carbon steel pipe making machines can yield significant cost savings for industrial manufacturers. According to a recent report from the International Pipe and Tube Industry Association, companies that upgrade to advanced machinery can reduce production costs by up to 30% due to increased efficiency and lower waste rates. High-quality machines not only enhance production speed but also improve the quality of the pipes produced, which can lead to a decrease in rework and material costs.

Tip: When selecting a carbon steel pipe machine, prioritize those with advanced automation features. These can streamline operations, reduce labor costs, and minimize the likelihood of human error, further enhancing efficiency.

Additionally, long-term costs should be considered alongside initial investment. A study by Research and Markets suggests that the total cost of ownership for low-quality machines can be significantly higher than that of premium models due to frequent breakdowns and maintenance. Investing in better machinery leads to reduced downtime and higher reliability, which is crucial for meeting production demands and maintaining competitiveness.

Tip: Evaluate warranties and service agreements when purchasing machinery. Robust after-sales support can save money on repairs and ensure optimal machine performance over time.

Upgrading to advanced pipe making machinery can yield significant returns on investment (ROI) for industries reliant on carbon steel pipes. The integration of automation technologies not only enhances production efficiency but also reduces labor costs and minimizes human errors. By implementing the latest machines, companies can ensure a more consistent product quality and faster production rates, leading to increased customer satisfaction and competitive advantage in the market.

**Tips:** One key benefit of upgrading is the ability to collect and analyze production data in real-time. This data-driven approach can help identify bottlenecks and optimize processes, boosting overall productivity. Moreover, modern machines often come equipped with advanced features like predictive maintenance, which can prevent costly downtime and extend equipment lifespan.

In a world where regulatory compliance and sustainability are becoming increasingly important, investing in advanced pipe making machinery can also assist companies in meeting stringent environmental standards. For instance, automation can significantly reduce waste and improve energy efficiency, aligning with global trends towards greener manufacturing practices. By leading the way in technological advancements, businesses can not only enhance their operational performance but also contribute positively to ecological goals.