In the ever-evolving landscape of manufacturing, the year 2025 is set to witness remarkable advancements in pipe welding technology and tube mill production lines. The innovations within the Pipe Welding Machine Tube Mill Production Line have been pivotal in enhancing operational efficiency, increasing productivity, and ensuring superior quality in the production of pipes and tubes. As industries strive to meet growing demand while adhering to strict quality standards, these technological breakthroughs are essential in driving growth and competitiveness.

This article delves into the latest innovations that are shaping the future of pipe welding and tube mill operations. From automated systems that reduce human error to advanced materials that enhance durability and performance, the focus is on how these advancements are revolutionizing the manufacturing processes. Additionally, it will explore key features and technological integrations that are setting new benchmarks in productivity and energy efficiency. Embracing these innovations not only contributes to smarter manufacturing practices but also positions companies at the forefront of industry excellence in the coming years.

The landscape of pipe welding technology is set to undergo significant transformations by 2025, as innovation continues to drive advancements in efficiency and precision. One of the pivotal trends is the integration of automation and artificial intelligence into welding processes. These technologies enable real-time monitoring and adjustments, ensuring consistency in weld quality and minimizing human error. Automated welding systems not only enhance productivity but also reduce operational costs, making them increasingly appealing for manufacturers aiming to stay competitive in a rapidly evolving market.

Moreover, the development of advanced materials and welding techniques is revolutionizing the way pipes are constructed and joined. Techniques such as orbital welding are gaining traction due to their ability to produce high-quality welds in hard-to-reach areas, while new alloy formulations are being developed to increase durability and resistance to corrosion. Additionally, enhanced training programs are emerging to equip welders with the necessary skills to operate increasingly sophisticated equipment, ensuring that the workforce is prepared to tackle the challenges presented by these innovations. By focusing on these technological advancements, the pipe welding industry is positioning itself for a robust future in 2025 and beyond.

Recent advancements in tube mill production techniques have revolutionized the manufacturing landscape, enabling greater efficiency and precision. The integration of automated technologies, such as robotic welding and smart sensors, allows for improved monitoring and control throughout the production process. These innovations not only enhance the quality of the final product but also contribute to a significant reduction in production time and labor costs. As manufacturers increasingly adopt these advanced systems, they can achieve higher production rates while maintaining consistent quality standards.

Moreover, the development of new materials and welding technologies is further transforming the capabilities of tube mills. The use of high-strength steel alloys and specialized welding processes enables the production of lightweight yet durable pipe structures, meeting the demanding requirements of various industries such as automotive and aerospace. Additionally, innovative cooling technologies and real-time data analytics are being implemented to optimize the welding process, ensuring that manufacturers can respond quickly to market changes and customer demands. This continuous evolution in tube mill production techniques highlights the industry's commitment to enhancing operational efficiency and product quality in a competitive global market.

In 2025, the pipe welding machine and tube mill production line are set to experience groundbreaking innovations that cater to the evolving needs of the manufacturing industry. One of the key features emerging in these advanced machines is enhanced automation. According to industry reports, automated welding processes can increase productivity by up to 30%, while reducing labor costs significantly. This automation not only streamlines operations but also ensures greater precision and reduces the likelihood of human error.

Additionally, the integration of Artificial Intelligence (AI) into welding machines is transforming the production landscape. AI-driven systems can analyze data in real time, enabling predictive maintenance that can enhance the longevity of the equipment. Industry forecasts suggest that machines with AI capabilities may reduce downtime by as much as 25%, allowing manufacturers to operate more efficiently and effectively.

**Tips**: When investing in new pipe welding machines, consider models that offer advanced automation and AI features to maximize your production efficiency and ensure quality. Furthermore, keeping an eye on industry trends and emerging technologies can provide a competitive edge. Regularly updating your equipment will not only keep your production in line with the latest standards but also help you adapt to changing market demands seamlessly.

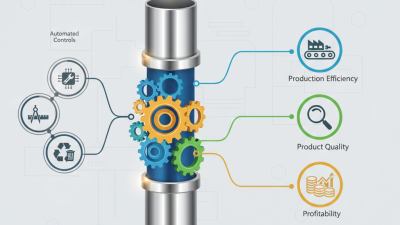

The integration of automation in tube mill operations is driving significant advancements in efficiency and productivity. According to a report from the International Federation for Automation and Control (IFAC), automation can enhance production efficiency by up to 40%, reduce operational costs, and minimize the occurrence of human error. Automated systems facilitate real-time monitoring and adjustments, which leads to consistent product quality and reduced downtime. A notable trend in 2025 is the increased deployment of Artificial Intelligence (AI) and Machine Learning (ML) algorithms, which allow for predictive maintenance and optimize the production workflow.

Furthermore, a study conducted by the Welding Institute highlights that the adoption of automated welding machines in tube mills can reduce weld time by as much as 30%. This increased speed not only amplifies output but also supports tighter tolerance levels in manufacturing, contributing to higher quality standards in finished products. As industries continue to embrace automation, the expected overall market growth for tube mill automation systems is projected to exceed 12% annually by 2025. This underscores the pressing need for manufacturers to adapt their production lines to remain competitive in an ever-evolving market landscape.

| Feature | Impact on Efficiency | Automation Level | Expected Production Increase (%) | Implementation Year |

|---|---|---|---|---|

| Robotic Welding Arms | High precision and reduced labor costs | Fully Automated | 30% | 2025 |

| Smart Sensors | Improved monitoring and quality control | Semi-Automated | 15% | 2024 |

| Data Analytics Integration | Enhanced decision-making and process optimization | Fully Automated | 25% | 2025 |

| Automated Pipe Feeding Systems | Reduced setup time and operational delays | Fully Automated | 20% | 2025 |

| 3D Printing of Components | Customization and rapid prototyping | Advanced Technology | 10% | 2026 |

The pipe welding and tube manufacturing industry is poised for significant evolution by 2025, driven by advancements in technology and automation. A recent report by MarketsandMarkets estimates that the global market for automated welding solutions is expected to reach USD 7.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.2% from 2020 to 2025. This growth is largely attributed to the increasing demand for high-quality, durable pipes in various sectors, including oil and gas, construction, and automotive industries.

One of the primary future trends in this domain is the integration of Industry 4.0 principles. Smart manufacturing techniques, including the Internet of Things (IoT) and artificial intelligence (AI), are set to enhance productivity and precision in tube mills. For instance, predictive maintenance technologies could reduce downtime by up to 30%, allowing manufacturers to optimize their operations. Additionally, advanced welding techniques such as laser welding and robotic systems are expected to lead to improvements in weld quality and efficiency, which could decrease production costs while meeting stringent regulatory standards for product integrity.

Moreover, sustainability will be a focal point in the development of pipe welding technologies. As industries strive to reduce their carbon footprint, the implementation of energy-efficient systems and eco-friendly materials will become vital. According to a report by ResearchAndMarkets, the environmentally sustainable materials market in manufacturing is anticipated to grow at a CAGR of 8.5% over the next few years. This shift not only caters to consumer demands for greener products but also aligns with global efforts toward reducing industrial emissions, thus providing a dual benefit to manufacturers.